|

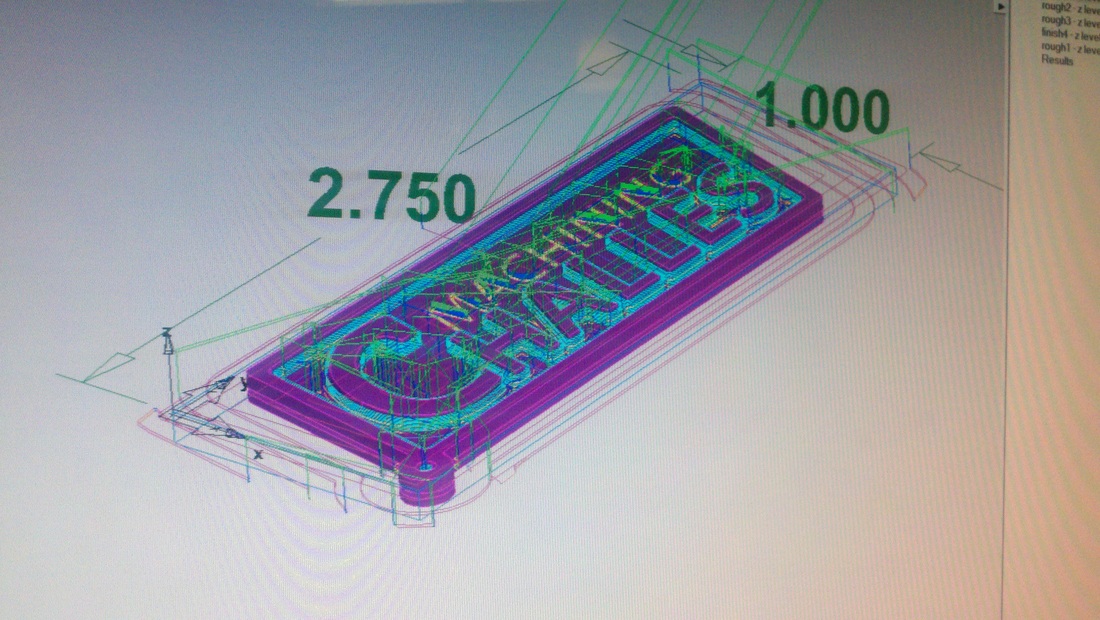

Today's entry is unrelated to trumpets. This is a review of FeatureCam, which is part of the Delcam family of software designed to make cnc machining easier on 3-6 axis machines. I say easier, because cutting complex designs is never easy even with the very best equipment, software and training. Coming from RhinoCam, I can say with certainty that FeatureCam is a huge upgrade in almost every way. _This is the third object I have cut with FC. This is a keychain I designed as a holiday gift for my neighbor who owns a machine shop across the street. I designed this in Rhino, saved it as an iges solid file and imported it directly into FeatureCam. After 20 minutes of creating features and adjusting cutting parameters, I had a post file for my VMC. Below is the part in the vise just after it was cut. This program used the following endmills; .250 Rough, .125 Rough, .0625 Rough, .0313 Rough and .015 Finish (for the smallest text). Total cut time was 32:48, which was longer than expected due to running my spindle slower than capacity. Spindle speeds ranged from around 5,000 to 18,000 rpm. I always use coolant when cutting brass despite what most machinists recommend. My tools last longer and I definitely achieve a better surface finish with coolant. These final photos show the keychain design after buffing and minimal surface finish blending. The raised text is 0.05" above the surface and the recessed text is .02" below. Check back for reviews of much more complicated trumpet parts in the coming weeks.

1 Comment

Abraham Navarro

10/21/2017 03:07:31 pm

Excellent contribution to the use of the FeatureCAM software, we look forward to more interesting entries, greetings.

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed