|

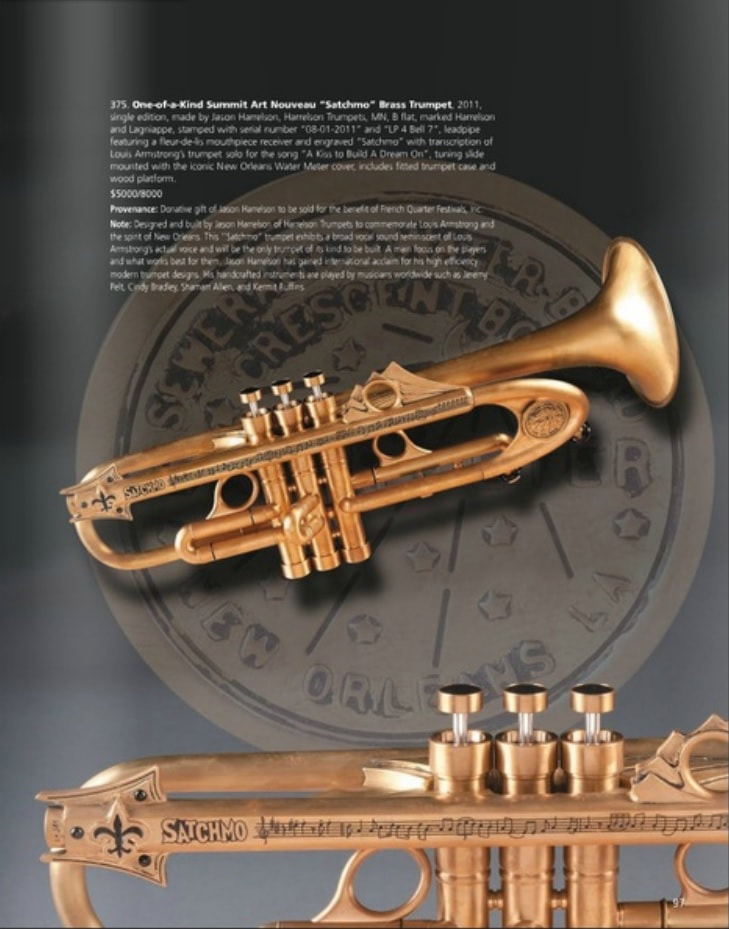

Regardless if they would work well for you personally, what do you think of these finger rings? Aesthetically, are they interesting? If you're answer is a resounding no, then I respect your opinion. And if you love them, that's perfectly acceptable as well. Ironically, I made this set of finger rings in 2010 in Minneapolis on my first industrial CNC milling machine. In 2010, I asked the public the exact same question. Almost everyone hated not just the finger rings, but much of my work in general. The consensus at the time was that I was messing with something that was already perfect, and that artistic embellishments were completely unacceptable. At the time, I was introducing one unique design after another, stretching what was possible for me to create in terms of machining difficulty, design intent, artistic freedom, and personal preference. Around the same time, I built the very first Satchmo Summerfest trumpet, which was auctioned off with all proceeds benefiting the non-profit that hosts the event. The first Satchmo trumpet incorporated the opening line of A Kiss to Build a Dream On played by Louis Armstrong on the leadpipe. And it also garnered a similar level of hatred from the online community with people claiming it was too extravagant, heavy, artistic, etc. This did not discourage me in any way as, I've understood since I was very young that, people are very slow to catch on. For instance, when I was around 10 years old I designed and built a Christmas ornament for my mother that used one AA battery to power a motor and an array of LED lights. Everything was handmade and soldered in my bedroom. My Mom thought this was amazing, or at least told me so, and she believed people would buy ornaments like this at the store. A few years later, I had evolved my skills to animating and lighting up decorations for Halloween. It was another 25 years before I saw anything similar for sale in the store, and these types of decorations are now overly popular, in my opinion. The truth is that I wasn't crazy about decorating for holidays. I simply enjoyed the exercise and challenge of making the animated designs. The funny thing about these Flames finger rings is that not only do people judge with their preconceived notions and eyes, but they also miss out on what is beneath. They miss the advantages resulting from 30+ years of researching SWE (standing wave efficiency) Technology, Maximum Bell Resonance, the Variable Performance System, and so much more. I haven't been focused on making cool looking horns all these years. I've been innovating the instrument we love to be easier and more rewarding to play every day. The artistic side has really just been a way to tie the aesthetics together with the technology to create playable art.

Full disclosure, I never have liked the look of the Flames finger rings. I simply made them to see if it was possible. When machinists visit my shop, they sometimes pick out one of these rings and tell me it must have been very difficult to make. Well, in 2010 my skills were not what they are today, and yes, they were very difficult to machine. That's exactly why I designed and made them. Jason

1 Comment

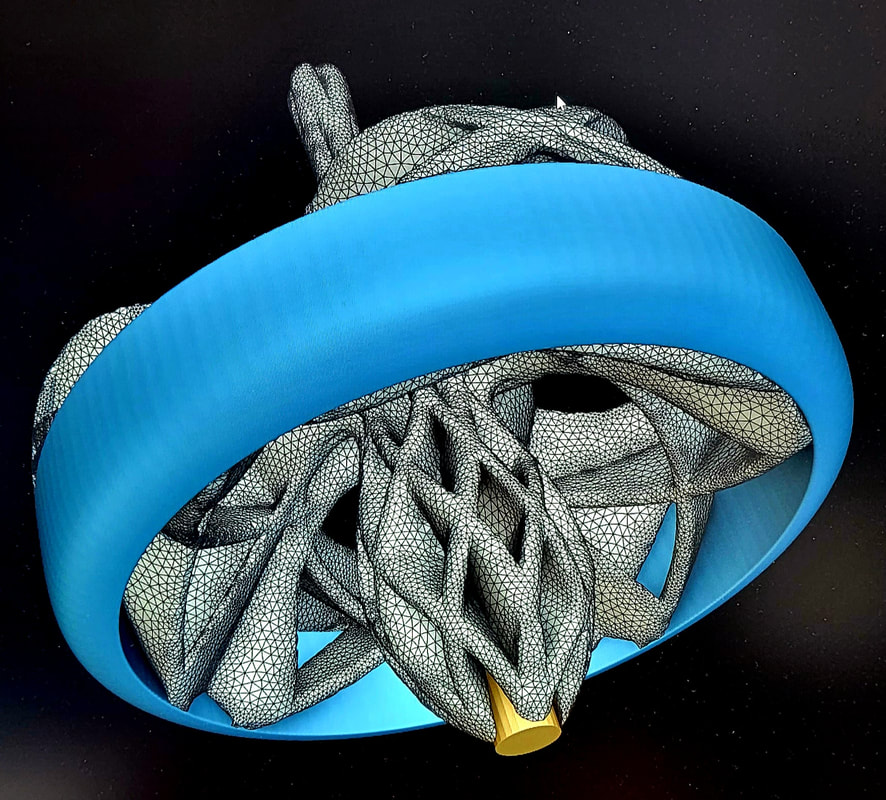

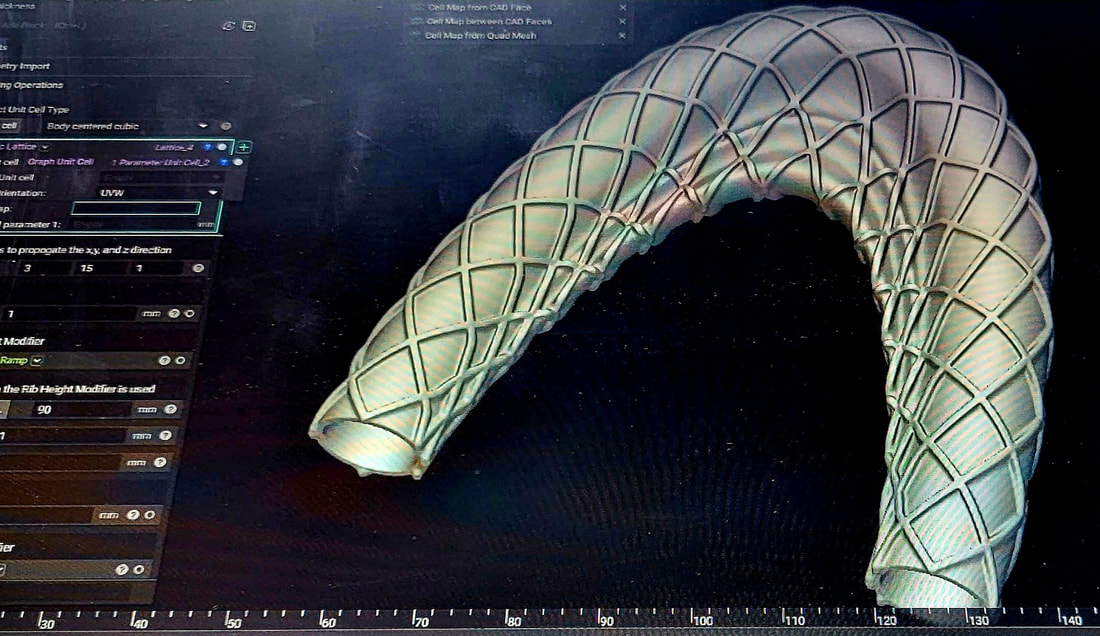

I just finished giving another shop tour. This was probably my 7th tour this month as we've had a lot of visitors this Summer. And on the tours, we discuss the future of Harrelson Trumpets along with our thirty-one year history. Tracing three decades of Harrelson research and innovation is a lot of fun. And we have numerous artifacts to show along the way, from the very first trumpet I ever built to instrument designs in progress that will be released in 2024. Shop tours are a constant reminder for Jen, Christine, and I to process where we've been, where we are today, and where we're headed. There's a robot arm waiting to be installed on the VMC along with a pneumatic vise to automate the production of bracing, tuning slides, and bell crooks. And there's a table covered with laser sintered metal parts showcasing the possibilities of modern 3D printing technology. Some of these parts fit our trumpets and are made in a wide array of materials including; aluminum, titanium, inconel, stainless steel, and nylon. All of these example parts are lighter, stronger, and better than their counterparts machined in brass. You will soon see entirely new generations of trumpets and mouthpieces made by combining laser sintering and CNC machining technologies. Where does that put us today? While I'm not 100% certain of the future, I do plan to push forward utilizing the latest Aerospace lightweighting software, laser sintering, and CNC machining to essentially enter a new era of trumpet design. This means that our current offerings of laser welded and silver soldered tuning slides and bell crooks will no longer be in production. In fact, the last production run using these techniques was in January. And with these innovations, our third generation of VPS Summit trumpets will also come to an end on September 30th. This is important for two reasons. One, the next generation of VPS Summit trumpets (G4) will debut this Autumn, at a higher price point. And two, our best selling trumpet design to date, the 3rd generation Summit will be retired ending the production run after 8 years. This means the Summit trumpets you see on our website are literally a few of only a handful of examples available this Summer. And this brings me to some really interesting and fun announcements. First, the Summit Illusion series was just released, which is a limited series of four variations. Two of these were designed for Jazz combo, one for Lead, and the last for versatility. We sold the first of this set a few days ago, and based on feedback from visitors, we expect the remaining three to sell this month. You can see the Summit Illusion here along with several YouTube video reviews. And through this Friday, you will receive a SpectraTone Blue mouthpiece, ProTec case, and worldwide shipping at no charge when you purchase an Illusion series trumpet. The next big announcement, I will be finishing several unique and rare builds in the Summit line featuring variations in bracing, engraving, inlays, and finishes. You may want to read every message I send through the end of the Summer just to see photos of these instruments. There's one exception to everything mentioned above. Those of you on my build list for a Summit G3 series trumpet may take delivery of your instrument based on your original order agreement. And if you're considering a new Summit in the current edition, you still have six weeks to place your order and set up a payment plan for up to 24 months. Every current or new Summit order is placed in our order cabinet WITH the required parts pulled from inventory. We are out of some style tuning slides and bell crooks permanently, and I see we only have 3 sets of style R remaining. Once these are sold or reserved, they are gone forever. I'm honored to have been chosen to build custom trumpets for well over two thousand individual trumpet performers, and look forward to exploring the future of brass playing with our Harrelson family. Jen, Christine, and I often discuss how our company is really the culmination of the shared vision and support of our entire clientele. Thank you all for this unbelievably rewarding opportunity. Jason

When it comes to bottom caps, I've pretty much heard it all. Before the internet was popular, the few people I knew who had any experience with trumpet equipment outside of traditional designs were skeptical about added weight except for one person. My college trumpet professor was the principal of the Minnesota Opera, and a great musician who happened to be obsessed with modifying trumpets. He encouraged me to experiment on brass instruments, which was something I was already consuming much of my time. Weighted bottom caps (and adding mass to every other component) were a topic of conversation in every lesson. The late 80's and early 90's were an interesting time in terms of trumpet design and performance. Most players were very traditional in their approach to pedagogy, equipment, education, and so on. Yet, new names like Monette got everyone talking, for better or worse. I began making custom bottom caps in 1992 after playing a trumpet with a set of heavy bottom caps. Having worked on cars with my mechanic father for years, I understood how and why mass would benefit a brass instrument, but had never thought to do it myself. Ironically, everyone I met seemed confused about how adding mass to a trumpet could change anything. I found myself in a position of disbelief trying to understand how all of my friends passed physics without understanding simple concepts like energy transfer. In the automobile industry, bracing, dampening, and light-weighting techniques were a prerequisite. Mounting a motor incorrectly could very easily cause excessive vibration at specific frequencies present in ranges of speed and/or rpm. As I continued modifying trumpets throughout college, my friends and I started producing blind studies to see if we could guess which trumpet, mouthpiece, bottom cap, or other variable was present in the excerpts we played for one another. I loved this game, and became skilled in hearing nuances in attack, sustain, release, tone color, projection, accuracy, etc. I was far from discovering MBR (maximum bell resonance) or VPS (variable performance system), but I was definitely on track to discover SWE (standing wave efficiency) principles. At the time, our group of trumpet players used the terms tight, open, locked in, slotting, and other words to describe what we were hearing and experiencing both from the perspective of the listener and performer. This was the beginning of my career, though I didn't recognize this fact for another decade. One common theme when adding weight to trumpets in the form of modified bottom caps, and sometimes top caps, was the perception of tone quality changes. We were convinced that heavy caps made trumpets darker. But the more I listened, the less I believed this to be true. And the heavy bottom cap myth was born between my friends and I. Since I was the only one who believed tone quality didn't change, I was basically considered a relatively poor listener among my peers. Then came the day I started my independent studies in brass acoustics as part of my education, which was halfway through my third year in college. My professor was an acoustics scientist employed by Yamaha to redesign a new line of guitars with the goal of making them sound and feel like a competing brand, but at a lower price. Such is the Yamaha template, which will likely never change. In my brass acoustics studies, I learned how to measure everything related to musical instruments from anti-nodal high pressure zones to understanding a complete spectrum analysis. Only a few days into my lab work, I started testing heavy bottom caps. And guess what I discovered! Heavy bottom caps do not, and cannot, change the tone of a trumpet. I do need to qualify that statement with the following. The trumpet being tested must be mechanically sound, free of air leaks, and be of a relatively good working design. So why do so many trumpet players insist that heavy bottom caps make their trumpets sound dark? I've heard a thousand arguments on this topic, many of which point directly to recordings where you can supposedly hear the difference. Well, the answer to this question is why I'm writing this article. I've covered this topic hundreds of times in clinics, lessons, and videos, yet it seems the vast majority of players still believe this myth. And here's why... We are not good listeners. Yeah, I said it. Most trumpet players are blinded by their personal feelings and experiences to the point of communicating with a very limited vocabulary on the very passion they preach, trumpet playing! To better understand what is happening when we compare a trumpet with standard bottom caps and one with heavy bottom caps, let's first define a few words. What does the word dark mean to you? What about bright? What is an attack and how can it vary? What is the sustain? And what is the release of a note? Have you ever stopped to define any of these basic words within the musician's vocabulary? I'll save you the reading, and let you look them up on your own, but owning these words is the key to discovering a world of new possibilities when it comes to brass playing. Heavy bottom caps added to any trumpet will increase the inertia of the bottom of the valve casings. Inertia is another word you need to look up right now, otherwise you're missing the point of this conversation. I reference inertia every day as this defines how much energy is required to set a musical instrument component into motion (vibration). Let's back up. When you play the fundamental (lowest pitch) on a trumpet, which is pedal C, your sound wave is defined by two nodes and one antinode. Imagine these as a long jump rope held by a person's hand on each end of the rope. When a third person skips over the rope, they are positioned equidistant from both people holding the ends, which is in the middle where the rope height is the highest. This high point exists in a standing wave inside a trumpet, and even looks similar, with the highest pressure in the middle. The ends of the standing wave, the nodes, are at the ends of the instrument. One end is inside your mouth wherever you have stopped the wave from traveling, which could be at the back of your mouth, or your tongue, or some other place depending on how you position your tongue and palettes. The other end of the wave is usually reflecting somewhere within the last few inches of the bell, or outside the bell up to a few inches depending on the pitch/partial sounded. Now that we've illustrated the fundamental, let's continue on with the first partial. By exciting the air column at the next highest resonant frequency, which is an octave higher, we will produce one more node and one more anti-node. This would be your low C below the staff on trumpet. If the fundamental produced an antinode in the middle of the instrument, where are the two antinodes on the first partial located? And what happens when you play the next highest partial, which is a fifth above the low C? How many partials can you add? Can you imagine where they would be mapped on your trumpet? If you've made it this far, give yourself a pat on the back. I have illustrated all of this in many YouTube videos, so you can always visit my channel and search for SWE Technology to get the visual. I know the science side can be a lot to digest, but playing the trumpet is literally a super cool science experiment that has been revised countless times over hundreds of years. And everything I do at Harrelson is in some way related to the science of the instrument and the science of our minds and bodies to become a seamless form of musical expression. Now I'll tell you why inertia and antinodes destroy the heavy bottom cap myth related to making trumpets sound dark. When we play any note with the exception of just a few, there is significant anti-nodal high pressure being confined within any brass instrument near the middle of the tubing. On trumpets and cornets, this is usually near the valveset. The louder you play, the higher the amplitude of the wave, and the more high pressure is exerted on the walls of the instruments, specifically at the anti-nodes. Depending on the design of your trumpet, there may not be sufficient inertia within your valveset (where the pistons are located) to prevent energy transfer from the sound wave into vibration of the confining body. All Bach, Yamaha, Schilke, Getzen, Kanstul, and hundreds of other trumpet models lack the inertia necessary to prevent energy transfer at the valveset. To take that one step further, only a few makers have ever addressed this problem, and even fewer have explored solving inertia deficiencies in the leadpipe, tuning slide, and other components. This means that when you play almost any note on almost any trumpet there is a transfer of sound wave energy into motion of the tubing and/or valveset. And this is not a small problem. The resulting sound wave degradation from inertia inefficiencies is huge. When you add a heavy bottom cap to any of the valves, you are increasing the inertia in that zone, which in turn prevents the energy transfer from anti-nodal high pressure within the tubing. Essentially, the standing wave will have less energy loss and more integrity making it sound closer to its potential. This added inertia improves the attack and sustain of any note with anti-nodes in that general location. It will not improve a note that does not have anti-nodes present in that location, which means not all notes are improved. Now let me ask you, does a note with more sound wave integrity sound darker or brighter? In reality, improving sound wave integrity improves all overtones by increasing amplitude on each with some exceptions. I'm really over-simplifying everything in terms of acoustics to make this digestible, but in general this is true. Technically, this means the note becomes both brighter and darker in terms of tone. But more importantly, less energy is required to produce the attack and hold the sustain as a result of higher standing wave integrity, which means the note is more stable. And that is the word we've been looking for all these years. Stability is increased. Why do we describe increased stability of a note with words describing tone color? Maybe because our musical community is obsessed with words describing tone? Or maybe because we haven't explored as deeply as we could, learning that the physics of the instrument truly affect very real challenges like attacking a note softly. Did you know that the greatest obstacle to attacking notes softly is inertia deficiencies within the design of the instrument? In fact, this and resonance are so closely tied to one another that the inertia design intent of some brands are the main reason they are superior to their competitors. Steinway and Bosendorfer discovered this fact before your grandparents were born. Unfortunately for trumpet players, the manufacturing techniques to apply this design approach were unavailable or not profitable until the last 50+ years. Even more disappointing, most of the instrument designers versed in physics were no longer employed by brass instrument manufacturers. Today, nearly the entire trumpet industry is focused on renaming the same designs with newly endorsed artists to sell you the same instrument they made generations ago with little or no design intent focused on inertia, sound wave integrity, resonance, etc. Adding heavy bottom caps is one way to preserve some of the sound wave integrity, but it is really the cheapest and least effective approach to a much bigger problem. In reality, the zones exhibiting the least inertia are the mouthpiece, tuning slide, leadpipe, and bell crook. You can't add heavy bottom caps to these areas because it's mechanically impossible. And this is why I have devoted the last 31 years to solving these challenges by designing the trumpet from the ground up. But that conversation involves dispelling many more myths! Let me know your thoughts on this conversation, and feel free to ask questions in the comments. Jason One last note. I'm hosting an open house in our Denver showroom and shop this Friday July14th. Stop by for a free clinic on understanding mouthpiece Rim variations, get a tour of our machine shop, and check out the grand opening of our music room where you can purchase vintage, rare, and new sheet music, cds, and vinyl. Please let us know you're coming by registering here... |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed