|

Today's entry is simply a recording of the first notes of the day. I haven't had a practice routine in about 8 years and I never do a warm up. Typically, I will pick up a horn in passing (as I'm walking by) and play for a minute or two, then put it down to work. Sometimes before or after opening/closing, I will practice for 30 minutes to a few hours continuously with no breaks. I usually do this as a free solo playing or with music on the radio of any genre. I almost never read music anymore, but when I do it is usually orchestral excerpts, cornet solos or something by vizzutti. It's a bit rough, but I just woke up and these are my first notes of the day...

Click here: First notes of the day

1 Comment

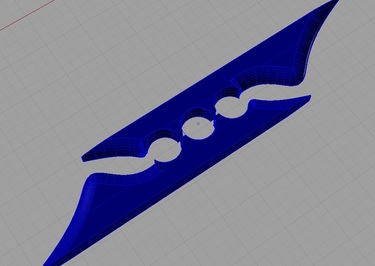

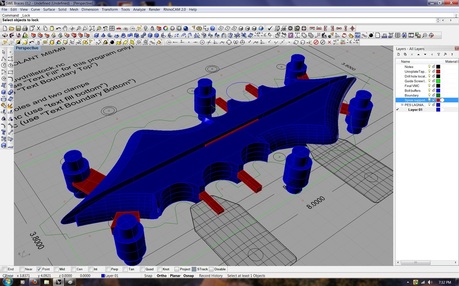

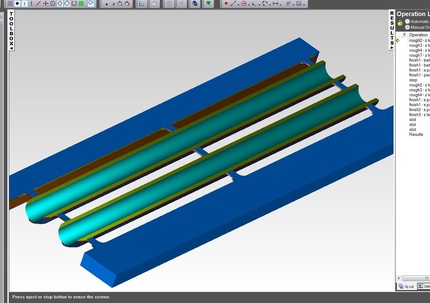

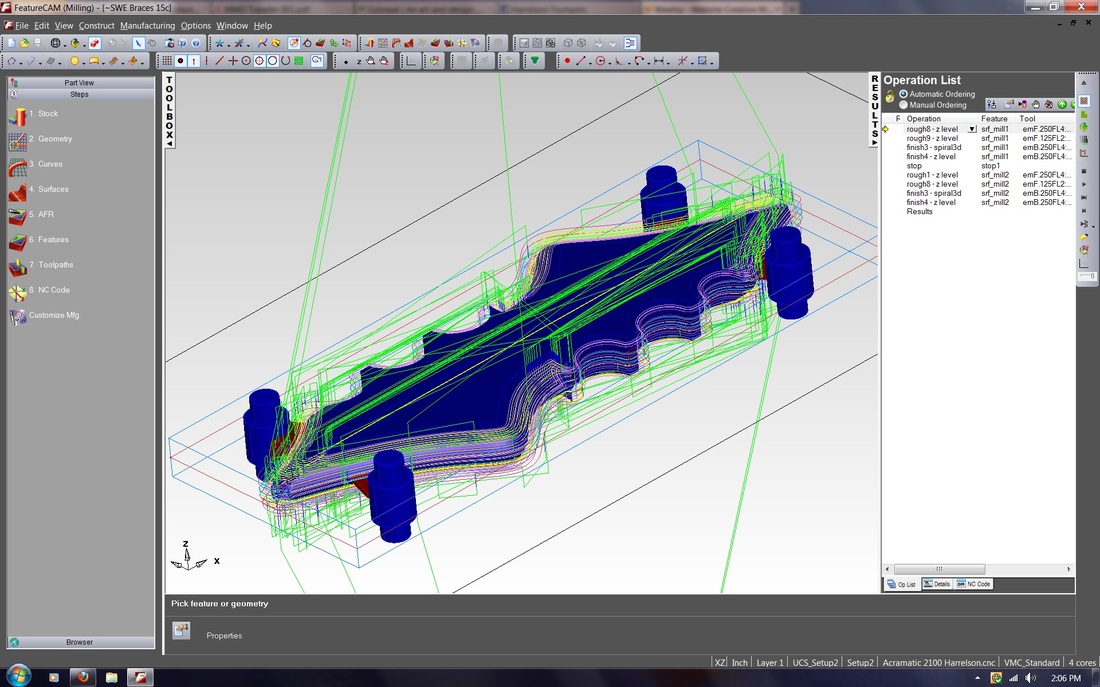

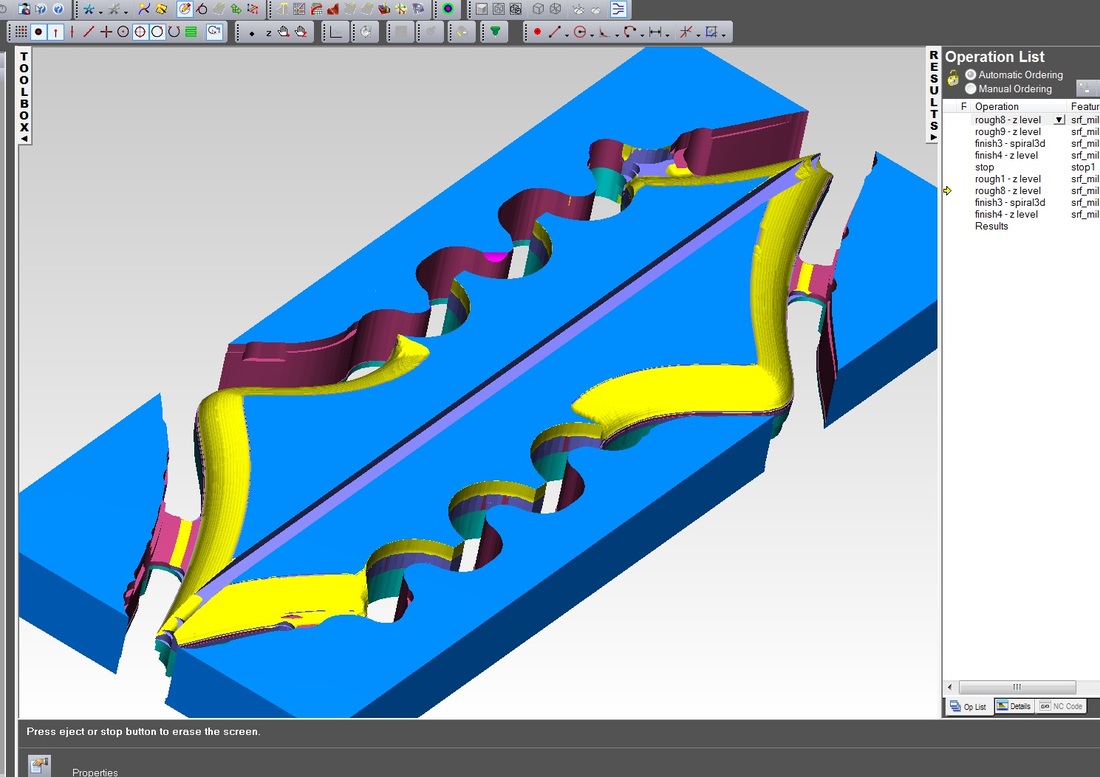

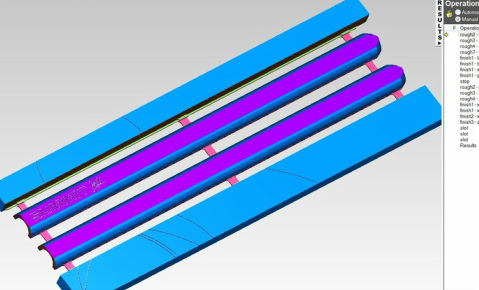

_As a test of machining more complex shapes with the latest CAM software, I have designed the new SWE Summit Trumpet. This instrument was commissioned by an incredibly fluent young jazz musician in his senior year of high school in the pacific northwest. Tree Palmedo's new Summit trumpet was specifically designed to be much more efficient than a standard Summit, hence the SWE designation. For those of you unfamiliar with SWE, this is an acronym for Standing Wave Efficiency, which is a basic physics principle used in my instruments. The new SWE Summit is not available for order as the production process is not streamlined. However, I did build two of these instruments and the second one will remain in our showroom for sale.  _What's so great about the new Summit? It features 1/2" thick top bracing that span over 14 inches, making this one of the most efficient horns built in the world. The leadpipe is also designated as SWE, built from two milled halves that are soldered down the length. I have created two variations of the SWE leadpipe thus far, one with the receiver and tuning slide tubes extending from the rectangular sleeve and the other flush. The Satchmo and previous New Orleans trumpets built in 2011 were the very first to incorporate the SWE leadpipe system.  _ I'll be adding photos of the finished SWE Summit trumpets later this week. This model is approximately one pound heavier than a standard Summit with the weight evenly distributed around the valveset. Future variations will include this design milled from Aluminum, reducing the weight by 65% while providing a solder-less dovetail slide lock assembly system. Other ideas that may come to the prototype stage include; adjustable dovetail finger rings, skeletonized material reduction, full artistic deep milled aesthetics and modular multi-part leadpipe segments. Now that I'm finished with this project and have "graduated" from my FeatureCAM software training on the mill, it is time to apply my knowledge to the mill/turn center...

|

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed