|

Many clients visit my shop and I witness a problem again and again, loose seating of the mouthpiece into the receiver. Are we so conscious of little scratches on the mouthpiece shank that we no longer fully insert the mouthpiece? Or is there another reason I am unaware of? I would bet over half of the players who walk in here insert the mouthpiece by pushing it gently straight into the receiver without twisting. What is the source of misinformation regarding proper mouthpiece fit and seating?

The mouthpiece taper originally began as a machine tool component, part of a spindle and tail stock in a lathe. Most lathes use a tapered modular system to date, though many are larger. The idea is very simple, two precisely ground male and female tapers mate together with maximum surface contact (friction) to transfer energy to the tool component and/or part to be machined. If you were to gently place a tapered chuck into the spindle of my lathe and turn it on, it would likely fly out and hurt someone or at least cause a dangerous situation. This is why lathes often require drawbars, which is a simple screw system that pulls the two tapers together until they lock in place. Considerable force is exerted by a drawbar ensuring maximum contact. The same should be true in trumpets and mouthpieces. The purpose of the tapered mouthpiece shank and receiver is to mate the two surfaces together until they lock solid. This ensures the mouthpiece will not fall out, but more importantly that energy is transferred rather than lost. I was working with someone last week who had just finished playing a horn and he handed it to me to oil a valve, the mouthpiece fell to the floor. In 26 years of playing trumpet, this has never happened to me personally because I was taught (by my Dad) to twist the mouthpiece clockwise (gently) into the receiver. This technique is also common in machine tool use and requires removal the exact opposite, by twisting counter-clockwise while pulling gently. If someone out there is teaching a different method, please consider the previous. Or, if you know another way that works, let us know! Either way, keep in mind that tapered mouthpieces and shanks have been around since the 1860's and they work great when mated properly, with gentle force and a twisting motion. A loose mouthpiece will most certainly rob the standing wave of energy and in extreme circumstances make the horn unplayable. Try it for yourself! On to electric cars, which have been around since the 1890's and for which I have had a sincere fascination with since childhood. Did you know that Jenatzy's electric car broke the land speed record hitting 65mph in 1899? Yep, that was 112 years ago and look at people rushing to buy little toyota and nissan toys that do basically the same thing, run on pure electricity. People tend to think I'm against little cars and the prius specifically, but that simply isn't true. I think it's great that so many people buy them, drive them and love them. They have a specific purpose and the market has responded to this need. I personally believe Americans would be wise to spend money with companies that re-invest and spend in the USA. A trade deficit does nothing to employ your kids down the road, nor does it help curtail the 3,476 overburdened government programs you may or may not believe are necessary to care for all the people in our country. I'm all for helping people (I go out of my way to help people all the time) so why not strengthen local economies and buy from companies that employ people who live next door? I'm just sayin'... Back to electric, my dream car would be built with my own two hands, but if I were to buy a new car today I would check out the Chevy volt (too bad it looks like a toyota) and the Tesla "S" or the Aptera. http://www.chevrolet.com/volt/ http://www.teslamotors.com/ http://www.aptera.com/

1 Comment

So I ran out of Bravura mouthpiece receivers this morning and set out to make just two of them for the next orders. One thing led to another and somehow I pressed the wrong button on my vmc which erased crucial information. No problem, I take very good notes so I looked up my handwritten numbers and punched them in...or not. It seems the last time I made receivers I had made several adjustments to the program and for some reason didn't take notes! I have hundreds of pages of notes that I never go back and read, but I needed this info now. Two hours later, I re-created what had been done before and I'm back to cutting the receivers. Not to mention my vmc only cuts the mouthpiece half of the receiver. I then chuck them in the lathe and cut the back end custom to each leadpipe so my vmc didn't save me any time this round.

It's funny how you can make plans, take care to ensure those plans are going to work and then something happens. In this case, I pressed the wrong button, but sometimes it's like the lady who honked at me (and everyone else) at the drive through this morning. She started screaming at me to hurry up so I rolled down my window and simply asked, "can't you be nice?". Her response was something about how she's late for work. So what did she do? Forced her way through the line (we're in vehicles mind you) and cut in front of everyone driving straight to the window to place her order. I live in Minnesota, this isn't LA or NYC...what is going on? Do people really think that because life isn't going as planned for them that they can take it out on everyone around them? I guess so. The irony is that they gave me her meal at the window and I had to inform them it belonged to the angry woman waiting in the parking space ahead. Maybe the lesson is that life doesn't always go as planned so we simply need to make the best of every situation? All I know is that I got to eat and I re-programmed my machine. Two curve balls, two strikes and then two home runs. That's how I try to deal with life's surprises. I don't know how many people read this, though Jen says it's sometimes over 500 hits a day, but you may have noticed I haven't been writing. This is simply due to crazy busy scheduling at HT this week. I have never had so many people interested in my work in such a short period of time. I'm grateful and welcome any and all business, but this may cut into my blog time.

The really good news is that I'm finishing orders the next two weeks and it looks like we'll be shipping close to 20 more horns before the end of the month. Thank technology I'm setting inlays tonight and realized something, WE HAVE NEARLY 200 INLAY OPTIONS. That's a bit excessive which is why only a few dozen are pictured on our website. However, I'm going to make it a goal of mine to add photos of a different inlays every few days. Let me know if you have any requests since it could take more than a year to photograph everything.

Thirty-six hours of rest and relaxation...I'm focused and productive this Sunday. Finishing numerous Summit and Bravura trumpets this week as well as at least one new Modular Bravura Demo. Be sure to check out my new Q&A sections...one is a Video Q&A and the other is in our online forum above.

So I have been working with a real prototype of the modular system for an entire day now and am coming to realize that screwdrivers, wrenches, nuts and bolts are highly overrated and rarely necessary. This little mechanism has been designed many times before, but for reasons unknown to me never made its way to the mainstream marketplace. Weird, considering how incredibly easy, precise and effective the slide lock performs.

I'm asking my readers to participate on this post and start giving me feedback on applications for the new slide lock system. Think about places screwdrivers and wrenches are a pain or time consuming, like furniture assembly, modular designs of any kind (bicycles, automobiles, home construction), linking mechanisms, etc. Please leave a comment if you have an idea you believe worthy of my time designing and machining and I may make one for you as a thank you. Imagine hanging a new door or installing windows in your home without tools. Create accessories and tool belts for any industry integrated with this mechanism on each tool. Hang or re-design your kitchen cabinets/accessories yourself with ease. Never lose your keys again with a system that prevents you from leaving them behind. Carry groceries to and from the car with one simple handle and all heavy/bulky items attached yet easily removable. Strollers now display an array of anything you need for your little monsters in your choice of easily accessible mounts. On vacation? Keep your camera, essentials, money, phone, etc all organized and in one place without the chance of leaving anything behind. The list of ideas is flooding my mind... Yes, the DMSLS (Dovetail Magnetic Slide Lock System) is done! I finished the prototypes last night. Now the next 2-3 days will be devoted to incorporating this system into a new demo trumpet with modular leadpipes and bells. Finally...

So I'm more productive that I was a few days ago...much more productive especially when designing on CAD software. That is thanks to another blog here;

http://gizmodo.com and here, http://gizmodo.com/#!5768510/the-best-deal-of-the-day where I recently purchased a 26" flat monitor that now easily displays four full viewpoints of my projects on one huge screen with all of my toolbars on my laptop. All this for $169.99 including shipping. I'm not usually one for plugging other websites or buying from China, but in the case of a monitor I'm not sure there are any alternatives. Thank you technology and mass production for making tools cheaper, higher quality and more accessible. I may not follow this business model, but there are certainly great advantages to a world of commerce that raises the standard of living for all who participate. On to aluminum guitars... Paul is a bass player looking for a new guitar so he posted in his blog that he'd trade a trumpet for a guitar. I offered to build him one (this would be my second) and he asked about aluminum. It is certainly possible and has been done before, but this got me thinking. Once the basics are designed, producing several would be relatively easy. So after the ITG, I will be ordering a massive block of aluminum and making chips. Other notes...Paul and I spent Sunday rebuilding the drive train on my 1997 Bravada and my back, neck and shoulders are still sore two days later. Maybe I should have bought that vehicle lift that sold at auction last year for $200? Have a nice Tuesday and remember to enjoy spring if you have it since we're still buried in snow here! So I had six appointments and one surprise visitor yesterday. It is freezing here, like all 6-month Minnesota winters, so it seems unusual to have so much activity from the outside world. Seemingly everyone wants a new trumpet this month, which is great news since we build trumpets! Today the largest local music store chain (family owned) buyers are stopping in to hopefully place their first order to be delivered in time for the ITG Conference. I have resisted the temptation and offers from dozens of dealers in the past, most of them international due to the simple fact that production has been limited by the number of hours I can work. However, thanks to new machinery, 21st century production techniques and efficient teamwork, I (we) are finally in a position to produce horns of a much higher quality, fit, finish and about three times faster than the previous methods.

So we welcome this crazy winter busy-ness and remind everyone that our horns are still built one at a time, by me personally, in the order deposits are placed. Jason You could not have convinced me that blogging would be fun six months ago. How could I know, I avoid the internet with the exception of my addiction to learning everywhere possible, which is sadly only a small percentage of the net. And yet here I am laughing at Paul's first two entries and the responses these have elicited.

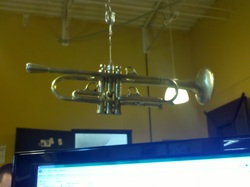

The photo in his blog of the Bravura hanging in the office is great. I was working on CAD designs the other day and realized I have always visualized everything without any physical example in front of me and exclaimed that I should hang a trumpet above my monitor, so I did. And Paul loves it! I can't believe I didn't do this 10 years ago. I devised a very simple lock system to hold or remove the horn from the harness in a second so I can pick it up and play it or simply point to a part on the suspended horn when answering one of Paul's sixty-two thousand four hundred and thirty-nine questions. Here's a shot from my desk... |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed