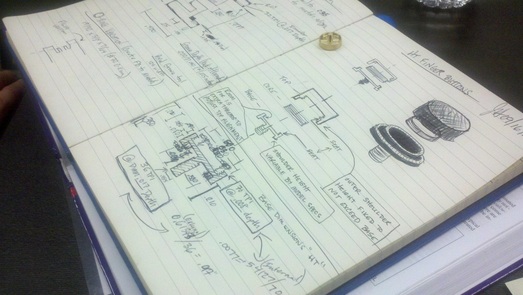

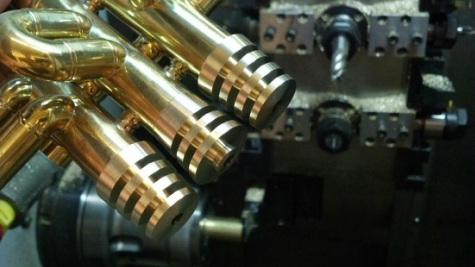

Summit Art C Trumpet Four months have passed since I've really stopped to think about what's ahead and what has been accomplished. The Minnesota leaves changed and fell to the ground in a matter of a few short weeks. Having lived all over the country, I have a hard time understanding why so many people enjoy this place of two seasons, one long cold winter and one very short unsatisfying summer. There's always talk of "four seasons" here, but after so many years I now realize it is little more than wishful thinking. I truly miss Montana this year, but that's another story. Today I am finishing up CAD designs for a Summit Art trumpet featuring the Boy Scouts Eagle, several sports team logos, double helix valve stems and numerous other custom options while running modular finger button inlaid caps on the 6-axis lathe. The shop is humming with running machinery and the smell of brass is in the air, just like every weekend. Sundays are my time to focus on challenging new projects without interruption.  I had the idea to create modular finger buttons around six years ago, but never attempted the design on a manual lathe as the fine threads and very tight tolerances would have been incredibly challenging without the aid of modern machinery. Last summer, I vowed to purchase at least a 4-axis cnc lathe to accomplish producing the vast array of intricate parts and systems filling my invention notebooks. I have a habit of re-investing almost every penny back into Harrelson Trumpets so saving the funds to purchase our current 6-axis lathe was relatively quick and two of our most loyal clients were kind enough to loan us the additional funds to purchase tooling, a barfeeder and other necessary accessories. Can you believe it cost over $20,000 to purchase tool holders, collets and cutters? That's the price for high precision machining on one of the world's most amazing machines. I'm thankful for all the technology available today even if it is so expensive. I have built over 800 trumpets using a manual lathe. Over 500 of those trumpets were built with the aid of a cnc milling machine of which I have owned 5 different models. Of that five hundred, around half benefited from our extremely accurate cnc vertical machining center purchased two years ago. And this summer marks the beginning of a new era in Harrelson Trumpets designs, production and customer service as we have put our new cnc lathe into service. Our new lathe will allow us to deliver ANY trim kit in a matter of a few days through the mail or within an hour when visiting in person. Need custom top caps, bottom caps and finger buttons to match for a vintage Martin? No problem. You want the parts to look identical to the original 1941 design? I can do that or you may choose from any of our new custom SWE designs as well. Speaking of new custom designs, I intend to introduce new designs every 2 to 3 months. Look forward to new inlay options, crystal cap overlays to protect inlays for life, wide body options, concave comfort shapes and intricate 2D and 3D milled artwork, monograms, etc. I enjoy combining jeweler-quality options with brass instruments. Why not have a horn that reflects you while adding beauty?  Back to the Modular Finger Button design, here's a photo of my sketches showing the three piece system. This consists of the Base, which is specific to the brand and model instrument such as Bach Stradivarius. The Base is similar to the bottom half of a standard finger button. The top half is a threaded hole that accepts the Core, which connects the Base to the Cap. The Cap is the part that is interchangeable allowing you to share a wide variety of styles and inlays between any horns fitted with the Harrelson Base. Now you can order your favorite inlaid finger buttons and years later, easily fit them to a different "favorite" horn. I plan to introduce modular top and bottom caps within the next year offering similar options that are less expensive than purchasing standard SWE Trim Kit parts. Someday, those monogrammed bottom caps you ordered will fit any horn in your arsenal. On the topic of creating solutions on the CNC lathe, here are a few of the new ideas you will soon see come to life: - Harrelson Water Keys, an improvement over Saturns these are intuitive, more robust and offer custom options - Modular Trim Cases for storing your SWE Trim Kit parts and accessories, these will be very inexpensive made from Delrin - Internal Mouthpiece Gap Measuring Device (GMD), did you know that mouthpiece gap varies between almost all brands? - Internal Mouthpiece Gap Adjustment Kit (GAK), now you can adjust your gap, see why gap is a deal breaker for everyone - External Gap Kit (EGK), available in several variations offering almost everyone the option to make your external gap disappear - Precision Valve Guides for all horns, made of Delrin, superior to brass or nylon offering smooth quiet performance - Air Speed Aperture Trainer (ASAT), this device is based on my extensive research and teaching on range, embouchure and endurance. Contrary to almost every product developed by other companies over the past fifty years, the ASAT trains you to develop aperture and air speed coordination to develop a beautiful sound at all dynamic levels in all registers. The fundamental idea behind the ASAT is directly responsible for my own control as demonstrated in my videos, lectures and private lessons. Playing high notes really has little to do with forcing lots of air or developing strength. Coordination is the name of the game! There is much more to mention here, but now I must get back to machining and building trumpets!

3 Comments

I've been meaning to write every few days to keep our clients, friends and fans informed on the daily happenings at Harrelson Trumpets. The high paced cycle of ideas becoming real horns and accessories around here is seriously astounding. I sometimes wonder how we can do so much so quickly while maintaining precision, personalization and artistry. The down side is that I personally do not have a life outside of HT and tend to work eighty to almost one hundred hours a week with days off more than a month apart. My blog entries are few and far between for the same reasons, but I'm working to remedy this situation. I will be presenting a lecture tomorrow in Schmitt Music's Auditorium (Brooklyn Center location) on the topic, "Building a Better Trumpet". Some of you have heard me talk about science, technology and the development of the trumpet in the past. Saturday's discussion will be fairly general offering insights into how and why we build trumpets in an entirely different way. I'll stick around as long as there are people asking questions or curious to blow on some horns. So hopefully I'll see some of you there! And I will make a very sincere effort to share my longest blog entry ever detailing most of my activities, travels, innovations and product developments over the past 4 months sometime this weekend. There's so much to talk about; new machinery, robots, our new HT members, Satchmo Summerfest, the Satchmo Trumpet auction, 5MM Modular Mouthpieces, Modular finger buttons, new trim kit styles, Adjustable Gap Receivers (AGR), our Caribbean Connections, the new Bravura S model, our current Trade Sales, our awesome clients and much more. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed