We like to invite visitors to the Harrelson Shop every now and then. Today's open house has given us an opportunity to unpack and organize after the ITG Conference a few weeks ago. Considering I build all the trumpets and parts myself, I prefer to limit visitors during weekdays so that I remain focused on designing, machining, soldering and assembly of instruments. But open house days are the exception, when you can come see live demonstrations of cnc machining acrobatics as well as trumpet performance acrobatics! Luckily, it is mild and relatively dry this fine Minnesota Saturday. Last week was tough on us in the machine shop with inside temperatures hovering in the upper 80's with high humidity. Oscar (our 4-pound shop dog) literally slumped on the floor all week long. Minnesota is a funny place with weather consistently miserable extreme dry cold at least 6 months a year followed by equally uncomfortable hot humid mosquito feeding for 3 months. The months in between are usually rain mixed with some really nice days that truly seem unbelievable to locals, but are likely the norm in other parts of the country. Today is one of those nice days that people will recall throughout the summer as temperatures and humidity rise high enough wilt just about everything in sight, including people. I personally love the hot humid weather and enjoy sweating through my respirator and safety glasses while I cut, grind, polish, bend, stretch and torch brass all summer. So take a minute to mark August 10th on your calendar and plan to visit the Harrelson Trumpets Shop during our next open house. James Knabe will be visiting for advanced SWE Training and we will have a full line of HT trumpets, 5MM modular mouthpieces and SWE trim kits on hand to play test. This is a great opportunity to ask me your burning questions about efficiency, design, manufacturing and performance techniques. I hope to see you there! Special thanks to Jolene for helping us stage and clean the shop this morning and for the tasty fruit basket :)

0 Comments

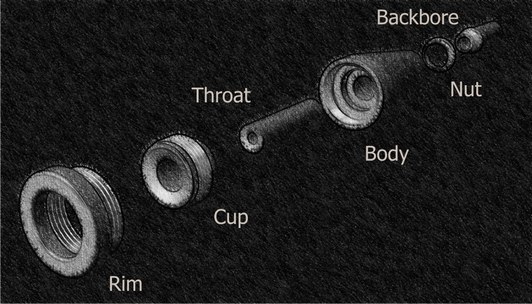

5MM Modular Mouthpiece System 5MM Modular Mouthpiece System This rendering illustrates all six components of the new 5MM Modular Mouthpiece System. The SWE Body holds the entire system together acting as the backbone of the mouthpiece. The Cup screws into the Rim with high surface contact threads increasing efficiency. And the Rim screws into the Sleeve with the same threading. In speaking with many of the hundreds of clients who have expressed interest in the 5MM System, I have encountered a few people who have trouble seeing the benefits of more options. In my little world, more options are the key to setting up anything to be just right. Could they have built a space shuttle or moon rovers without a lot of custom options? Or would it have been possible (or just as easy) using off the shelf basic nuts and bolts? Hopefully, the answer is obvious, but this next illustration is for those of you with doubts. Imagine that during your pursuit to become a great trumpet performer, you eventually purchased 10 different mouthpieces at an average of $50 each to find one that worked right for you. Yes, this does happen. In fact, it happens all the time. I personally know hundreds of players who literally own more than fifty mouthpieces and I have heard of some players owning more than one thousand. How much would that cost and would the 5MM be any better of a solution? Let's take a look... Buying 10 standard mouthpieces will give you 10 possible variations or $50/variation at $500. However, spending $495 on the 5MM will give you 120 variations at $4.13/variation.  5MM Backbore variations 5MM Backbore variations Here's the math: 10 mpcs @ $50 = $500 19 piece 5MM Set = $495 Includes: - 2 Rims - 3 Cups - 5 Throats - 4 Backbores - 4 Nuts Total number of possible variations: 2 Rims x 3 cups x 4 backbores x 5 throats = 120 configurations The 19 piece kit also includes 4 lock nuts of various lengths to make your 5MM appear seamless with your AGR or standard receiver on multiple horns. So you can spend $500 on 10 mouthpieces and leave 8 or 9 of them on a shelf collecting dust. Or you can invest in 120 variables that will lead you to the best mouthpiece that fits your varying requirements because YOU designed it! Many of you are wondering, "How would I know which parts to buy and why?". The answer to this question and many more will be explained in detail in future posts along with graphic guidelines and a simple set of rules that will minimize your time, energy and investment as you discover the best 5MM configuration that fits your specific embouchure, playing preferences, intonation requirements and desired tone. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed