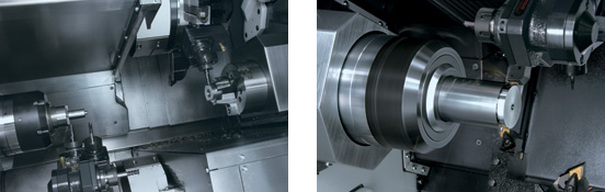

Every few days, weeks or months I start thinking, "what next?". That's likely how I came to be the owner of Harrelson Trumpets in the first place, one thing led to another and so on. I received news last month that the small machine shop in Portland, Oregon whom I have worked with very closely over the past 6 years is letting me go as a customer. It seems that by continually producing more and more of my own parts, while our orders with the machine shop were shrinking in size and profitability (for them), they decided we were not a good fit for their business. I asked the owner what changed and much to my surprise, he has seen a huge increase in machining orders. This is good news for him (and US manufacturers) and probably good for me too. Now I know what comes next...a new cnc turn/mill center!  Here's where things become challenging. The new cnc turn/mill center I would ideally purchase to produce the very best parts using completely new innovative designs costs almost $600,000 from a US manufacturer. Hmm...I charge a fair price for my horns. I build each of them myself and you'd think there's a lot of profit, but there isn't. My horns are expensive because they require so much time to design, machine, assemble, test, etc. so there is very little profit at the end of the day. So how do I come up with $600k for a new cnc machine that will change the brass world as we know it? The simple answer is, "I don't". I have spent the past 4 weeks glued to online auction websites (which is where I purchased the majority of our tooling in the past 10 years) looking for that perfect machine in good used condition built within the last 10 years. Now I'm in the the $60k price range before tooling (another $15k) and software (add another $15k), so $90k for a machine that does 1/3 as much and is ten years old. Wow, the realities of machining are sometimes overwhelming. I've already invested every penny into possibly the most modern brass instrument shop in the world when you include new production processes, design and cnc software, etc. And I still see a shop that's only half capable of my ideas. Either I'm too demanding or my equipment is lacking.  So here are my ideas and I'd appreciate feedback from anyone and everyone reading this entry. I pretty much have my mind up on what I'm going to do, but here are all of my current considerations... 1) Hire another machine shop to make parts to maintain our status quo (I hate this option) 2) Increase production slightly by charging considerably more for custom artwork and special designs, which will result in more time at my bench (building trumpets) and less time in front of computers (creating new designs). Save the profits from the extra sales from increased production and purchase the new machine with cash. 3) Go to the bank and finance the machine. I take pride in the fact that I have never borrowed a penny to purchase a machine or equipment. This means a lot to me and even though most of our society borrows for large purchases, I have always bought cars and machines with cash I have saved. Owing money to anyone is generally against my code. 4) Start a "Kickstarter" campaign on www.kickstarter.com where I pre-sell the world's most innovative 5-piece modular mouthpiece system and if all goes well purchase a less expensive machine made outside of the USA. (sadly, a machine made outside the USA is probably the only option) 5) Accept private investments from friends and clients (who have been requesting to invest in my company for years!) and reward them with new mouthpieces and possibly even a trumpet based on their investment. What other investment opportunity pays interest AND a free horn? (even though this goes against my investment rule, it would be very rewarding to partner with people who believe in my work rather than a bank AND this would give me the opportunity to test designs directly with investors who have a stake in the success of my products. Win-win.) At the end of the day, I have already temporarily solved the problem so Harrelson Trumpets clients do not experience much of a delay, if any, on their trumpet, trim and mouthpiece orders. I am currently building a complete vertical lathe system of my own design as a custom option on my VMC. This simply means my vertical milling center will become a vertical lathe within 2-3 minutes of jig and chuck installation allowing me to cut everything we currently have in production quickly and easily. However, this only maintains status quo AND it ties up a machine that was designed (and is used) to produce many other important parts. I can retrofit my machine to do a million different things, but in reality it will be tedious as a solution to this problem considering the high number of cnc turned parts we currently have in demand. Problem solved, for today! But tomorrow, "what comes next"?

5 Comments

Luis

7/21/2011 08:50:13 am

Hello:

Reply

Mike Jones

7/21/2011 10:28:09 am

Option 1, but place larger orders and drive down your piece cost. If you can't drive and immediate ROI with your current business model, you're putting too much risk into your business. Is your core competency running a CNC Machine or designing great horns? It's clearly desiging and assembling great horns. You don't need 100% capacity of a CNC machine so you're over buying to have the excitement of a new piece of technology. Stick to your core competencies, outsource the rest. You have a website... did you buy a hosting company to run it or did you buy the capacity you need to run your online business?

Reply

7/21/2011 11:40:41 am

Jason,

Reply

CB

7/21/2011 12:27:47 pm

Whatever option that keeps your quality and production at the highest levels and prices at current or lower rates after weighing everything out carefully would be the best one lol. Keep up the good work JH

Reply

JH

9/18/2011 01:47:46 pm

In the end I decided to pay cash out of my own pocket for the new cnc lathe. I could borrow money, but that just isn't my way. So many finance and business-minded people think I'm nuts for buying machinery with cash up front, but to me it isn't about the numbers, it is about the usefulness of the asset and mental focus on my goals rather than bills and contracts. Maybe I see my business more as a vehicle for expression than a money-making machine. To me, it is all about the journey learning new things everyday, if not every couple hours.

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed