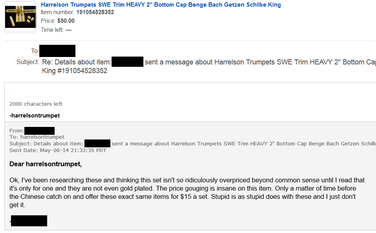

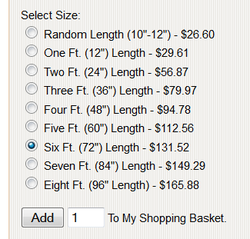

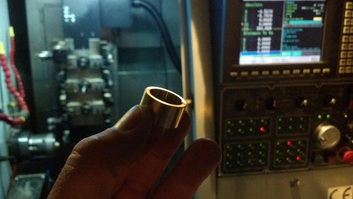

I came in to the shop late today getting in at 6:45 rather than my usual 5:45 as I decided to sleep in one extra hour since I didn't go home last night until almost 8pm. I was greeted this morning by two messages from a prospective buyer on eBay who was venting frustration with my, "unfair" pricing, which further encouraged me to finish this blog draft. If you are not interested in hearing my opinions on high quality precision manufacturing of innovative physics-based trumpets and accessories, now is your chance to click the back button! Having endured criticism for most of my life, I have come to understand that the intent of those offering advice is usually to inform, challenge or even change my behavior. I get it. You have a different perspective and you feel compelled or even obligated to let me know that I'm not on track with your personal expectations. Perhaps you see others in my role saying and doing things differently so you expect the same of me. Criticism can definitely be constructive, positive and very helpful so I welcome your thoughts. But take into consideration that I have my own perspective based on personal experiences, thoughts and intentions. I may not make choices based on a lack of knowledge or information as often as you may think. This reminds me of an interaction I had with a young person through the comment option on one of my YouTube videos where I play tested and criticized a Monette trumpet. I was selling a Monette trumpet that was traded towards a new custom Summit and reviewed the horn on YouTube. The title of this video states, "Of all the high end trumpets Jason has play tested this year, this Monette was the most difficult to play a three octave C scale." And within the video I mentioned that the notes in the upper register did not lock in tight, meaning I had a difficult time landing on the intended pitch. Here's a link to the video or you can watch it below. The viewer's comment read, "What I would like to see is a fair test. A new 30th anniversary raja monette with integral mouthpiece and new summit horn. None of this picking up an out of date monette horn and using to represent the quality of all monette trumpets. Not fair or mature." And my response, "I welcome your challenge! Bring in your 30th Anniversary Raja and let's play some duets switching horns. Great horns are timeless my friend." My suggestion was a real-world test where we played a new Summit and a new Raja to truly experience the differences and have a conversation. This person was criticizing my own criticism of this trumpet implying I had no real experience with newer models. In reality, I have owned eight Monette trumpets made between 1994 and 2012. These have included the STC, 900 and Ajna II series with one being a Raja variation. My experience with Monette instruments is substantial as I have repaired and modified numerous examples that came in for repair or upgrades. In my opinion, Monette instruments are very high quality and are definitely easier to play than most factory built trumpets. I truly appreciate the innovative side of this company. However, Monette is faced with the same challenges as all other manufacturers concerning subjective adaptation, efficiency, impedance, resonance and the laws of physics. And until they address their weaknesses in design and construction, the same problems will exist within this brand of instruments. I am stating this from first-hand experience playing dozens of examples with the perspective of a solid understanding of physics and trumpet performance. They do great work, but like myself and all others, they could do it better. I am a very open-minded person with a critical mind. I appreciate those who pursue their own vision giving their ideas shape and structure until they are thrust into physical reality. I appreciate those people so much that I mentally consider what they could have done better. This is my internal criticism at work and I apply this to my own vision more than all others. I am literally the most critical advocate and initiator of change within my reality. Essentially, this means I spend a lot of time thinking about what I could have done better and then I go do it better!  Getting back to the subject of criticism, the prospective eBay customer I mentioned earlier was upset by my pricing of SWE Bottom Caps and full trim kits. I am guessing the person is equally as concerned with the pricing of my instruments as is apparent upon reading the message in the photo to the right. He states, "Ok, I've been researching these and thinking this set isn't so ridiculously overpriced beyond common sense until I read that it's only for one and they are not even gold plated. The price gouging is insane on this item. Only a matter of time before the Chinese catch on and offer these exact same items for $15 a set. Stupid is as stupid does with these and I just don't get it." Clearly this person is under the impression that my company is charging too much for bottom caps! He also seems to think that Chinese manufacturing is the solution to his "pricing" problem and it is only a matter of time before they will start offering this product for $15 a set. As you can imagine, I have a lot to say about this message. But first let me thank eBay member "dxxxxx7" for the constructive criticism. You have encouraged me to give perhaps the longest explanation in history on pricing an eBay item. As a side note, did you notice priority shipping is only $5? The first question that comes to mind, "Why do you need these bottom caps in the first place?" This is an important question as it may reveal why this person believes the pricing is a problem. Assuming this person is male, he states that he has been researching "these". Considering my company is the only company offering SWE products, I would assume his research would only lead back to my website. SWE is short for Standing Wave Efficiency and despite years of layman criticism, it is true physics applied to brass playing. SWE products do in fact increase efficiency in all brass instruments improving stability, slotting and flexibility. I'm guessing that he did not research SWE, but rather looked up "heavy bottom caps" as he does not realize SWE is what he is really purchasing here. This brings up an interesting piece of psychology and having been a student of the mind for most of my life, I enjoy breaking down the decision making process within individuals. This person is most likely interested in my SWE Bottom Caps solely based on the visual information depicted within the photos. Why? Because most of us trust and act upon visual cues more often than real information. You don't believe me? Consider the scenario where you are driving to work in a hurry because you left home a few minutes late. You see flashing red and blue lights in your rear view mirror and pull over to the side of the highway. Your first thought quickly turns into many frantic thoughts, "oh no, I was speeding but how fast was I really going? ...did I stop at that last stop sign? ...where's my insurance card? ...registration? ...I'm going to be late!" The police officer sits in his car for what seems like an eternity before walking up to your passenger side window... But how do you know this is a police officer? Were you really speeding? Based on the visual of the red and blue lights behind you, it is possible that you fabricated all of those frantic questions as a form of explaining the situation. Did you even check to see if the car behind you is in fact a patrol car? Why not? Almost all of us will pull over and assume we are dealing with a police officer based on the red and blue lights. I know this from first-hand experience since I am a former Las Vegas police officer. Your brain will trust visual cues blocking out almost everything else during critical decision making moments. The evidence is overwhelming and the mountain of published studies would take a lifetime to review. Almost all of us pull the trigger on a purchase or action based on the neurons firing in our brains after our visual cortex is fed images that we deem satisfactory.  The "visual" thought process goes something like this; I see cool bottom caps... must have cool bottom caps... oh my, how can bottom caps be so expensive? I would step back for a minute and let go of the visual information. I personally do not want you to buy my products based on how cool they look. I do take in pride in making things look appealing, but my vision involves much more. I want your brass playing to improve. I want to help you succeed. This is one of many reasons I love my company, my products and working with musicians from every walk of life from every corner of the globe. I encourage you to take the time to know what you are purchasing and why. Making decisions based on the visual is similar to not thinking at all. Would you give your son or daughter $300 or even $3000 to buy something special only to learn they bought something based on how cool it looked? Likewise, reconsider products that are heavily endorsed by famous artists or celebrities. Are you purchasing an endorsed product for the value it brings to your experience or did you simply recognize a name and face? Dig deep and learn as much as you can about what you purchase as being an informed consumer will often bring greater rewards. To be clear, the SWE Solutions that I offer are valuable to brass players due to increased Standing Wave Efficiency. They are much more than big chunks of brass. And in reality, I personally do not recommend sizes larger than 3/4" as the law of diminishing returns applies. Unless you really like the look of 2 or 3-inch bottom caps or you have more money than you know how to spend, I would choose something smaller. But what about price? Each 2-inch SWE bottom cap costs $50. That is the individual price so a set of three costs $150! I agree, that is a lot of money for one set of bottom caps so let's break down the cost to better understand my pricing.  First, let's consider the price of solid Brass (alloy 360) rod which I purchase in 1-inch diameter bars in 6-foot lengths. Today's cost of one bar is $131.52 according to my supplier, but the price fluctuates daily. By dividing $131 by 72 inches (6 feet), the cost per linear inch is $1.82. Now let's consider how many 2-inch bottom caps I can make from one 6-foot bar of brass stock. My CNC Lathe can only feed bars 32 inches in length so I must cut the bar into three pieces, two measuring 32" and one remnant 7-3/4". The missing 1/4" became chips the width of the saw blade I used to cut it. Starting with one 32" length, I can safely produce fourteen 2" bottom caps. Here's the math... 2.0" + .125" (cut-off tool width) + .005 (facing) = 2.13" per bottom cap. Dividing 32 by 2.13 equals 15.02. This means I can safely cut 14 bottom caps and have around 2.18" left. Why can't I use the last 2.18" to make a 2.13" bottom cap? There is not enough material left to safely hold the stock while it is being machined. To save you the trouble of reading more long-hand math, I will give you the results. I can cut 31 of these bottom caps from one 72" bar of brass. The cost of material is $4.24 each, which is relatively expensive when compared to cheaper materials used in mass manufacturing processes. Now let's consider the machine used to precision machine all round SWE accessories. My CNC Lathe is actually what is known as a Mill/Turn Center. This means that it was designed to turn the stock and remove material with cutters moving in the X and Z axes. And it also turns special live milling tools like a milling machine in the X, Y, Z and C axes to remove material. In addition, this machine incorporates a sub-spindle so that the part may be transferred from the first cutting operation to the second where the part is finished with turning and milling in one complete setup. The entry level price for a machine with 26 tools, live machining and a sub-spindle is well over $200,000 and most of them run $300k+. Now let's consider the cost of tooling, machining time, maintenance, my time, the time of my employees and the cost of keeping the lights on. The largest expense in our company is also our greatest asset...our team! I usually refer to Harrelson Trumpets as "Our Company" since there are five individuals that work tirelessly to bring you innovative cutting edge solutions. I machine everything personally including all hand work required to shape, fabricate and cut materials within the vast majority of components in our trumpets and all accessories. I do all of this myself for many reasons, but mostly because I love the challenge of doing things right. Precision machining is almost a way of life. Sure, I'm messy when I play a solo chorus in a Jazz combo, but when it comes to building trumpets (or anything) I'm all about precision, intention and quality. I put 100% of my focus and energy into creating products with my name on them so I really do care about every single little piece of the process. I earned around $30,000 last year working over 4200 hours so I may be one of the lowest paid precision manufacturers in the country. But at the end of the day, I am doing what I love and I believe reinvesting in our company is more important than having more money. The rest of the Harrelson Team is extremely busy as well. James regularly logs 45-50 hours a week performing final solder removal, clean-up, brushing and plating/lacquer preparation of trumpets and accessories. He also cuts, polishes and sets solid stone and other material inlays into finger buttons and bottom caps. Christine works on inlays as well while heading up our customer service role. She answers the phones, most email messages, handles billing, shipping and logistics and she operates the CMM (coordinate measuring machine) to measure customer mouthpieces for reproduction within the 5MM system. Jen handles most of our Public Relations including social, web and print media while working directly with clients on interviews, photography and the visual side of our company and products. And James Knabe has dedicated himself to traveling the country offering masterclasses and clinics on trumpet performance and Harrelson trumpets and accessories. He is your opportunity to try our horns in person no matter where you live across the USA. The greatest cost in producing SWE Bottom Caps is handling each item so many times. Unlike Chinese factories where the focus is on producing a large number of items resembling the original, we make sure every item that goes out the door is made to our high standards in design, function and finish. How much time is involved in delivering a 2" bottom cap?

The complaints by eBay member dxxxxx7 helped reaffirm something that has bothered me for many years. We live in a world of low standards where the monetary price is most often considered the best choice. This cheap mentality has been propagated by chains like WalMart, eBay, Taco Bell and has spread to almost all product lines including computers, automobiles, groceries, homes and now brass instruments. Of course cheap trumpets have always been available, but the general attitude that all things should cost very little money is relatively new. The major difference between Harrelson Trumpets (custom precision machining with real intent to make an innovative product) and cheap mass produced Chinese parts comes down to a few basic elements;

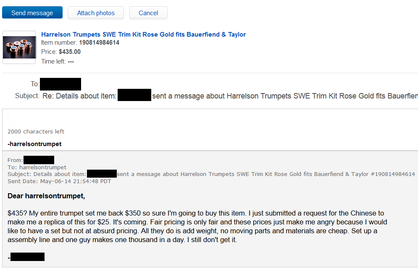

I received two complaints from this eBay member, the second is shown in this photo. He exclaims that, "Fair pricing is only fair and these prices just make me angry because I would like to have a set but not at absurd pricing." When did society shift towards the attitude that "Fair" is reflected in a low price for the consumer? Who created the business and all the processes involved in bringing these products into existence? And should that person (me) not be paid a "fair" wage? A cheap product was once considered the least attractive option. The cheap option was reserved for those rare times when the product would only be used once or twice or possibly consumed/destroyed within the process of use. An example would be purchasing cheap batteries for a flash light that you knew would only be used once or twice within the next few weeks. It would be counter-intuitive to purchase cheap batteries for a flash light you may need in an emergency three years from now for obvious reasons. The same is true of a shovel. It may sound like common sense, but you wouldn't buy a cheap shovel that is likely to break due to poor quality, workmanship and design if you were going to dig all day. Sadly, much of our society has caught the "Cheap" bug and the infliction is apparently leading to full fledged entitlement issues. Claiming that a price is unfair is ridiculous and I don't care which product you are referring to including the cost of gasoline, a steak dinner or a nice hotel room. The price of a product is an agreement between a buyer and a seller to exchange money for goods or services. If you don't like the price, don't buy the product. And if you believe the price to be unfair, take a minute to consider what is involved in producing that particular product. I know thousands of people who believe gasoline is unfairly over-priced yet they have failed to show me an alternative product or process that will fuel a 4000 pound vehicle to travel 22 miles per gallon for $3.50. How much would you charge to personally move 4000 pounds a distance of 22 miles? When you think about the value of gasoline, it should probably cost around $30 or even $50 a gallon, but thanks to an entitled cultural attitude we lazily complain. How much does an oil drilling operation cost? How about an oil refinery? What about distribution and safety? Gasoline is one of the least expensive valuable commodities you will ever purchase! The only time the price of a product could be deemed unfair is in the case of hidden fees, taxes or other costs that are not directly reflected within the intrinsic value received, but that's another story. So dxxxxx7 wants a cheap trim kit costing $25 for his cheap Chinese trumpet that cost him $350. That's fine by me, but why stop there? Why not add a cheap car and gasoline so he can drive to his cheap paying job where he serves cheap burgers to other cheap people so he can pay cheap rent? At the end of the day, a cheap paradigm will buy you nothing but a cheap world. Where will you find innovators, dreamers and artists in a world of cheap mass production? Most likely sketching ideas on napkins. Then turning those first few ideas into something that resembles their initial vision until someday, many dedicated years later, it blossoms into a world of previously unimagined beauty inviting all those with imagination to explore, grow and understand on a new level. And what is the cost of this new world of possibilities? Anything but cheap because those who raise the bar to a new level have spent all of their time, energy and money creating this new reality. It is there for you to enjoy if you're not too cheap to jump in and try it for yourself. I started this company with nothing but ideas. I had absolutely no money, no experience, no skill, no mentors, no education and no allies. I created value where there was none by devoting my entire mind, body and soul to advancing brass instruments. My products are extremely valuable, rare and worth every penny. I know this to be true since I designed, built and tested every one of them.

20 Comments

5/7/2014 05:38:08 am

I am a HUGE supporter of and for high quality goods and enjoy having choices too. Much of my life my friends have asked why or how I could pay so much for things like shoes or purses or cars or electronic devices and the response is always the same. At the end of the day I pay more because I'm getting WHAT I want and the quality of it. The math on that is that I enjoy a high quality this or that for a long period of time and they end up buying many different of whatever it is due to the products lack of quality and in the end might spend the same amount of money (but more time as their products breakdown and they have to buy new ones. So while I'm not against buying a six dollar pair of jeans from Target (the ones I'm wearing now) I am against people who think that fair business/fair price=fair quality is unfair. THAT belief in itself is just that, unfair.

Reply

Greg Zent

5/7/2014 06:04:33 am

Bravo!

Reply

Jazzman Shane

5/7/2014 06:12:49 am

Hey davlippo7---

Reply

Paul Herlein

5/7/2014 09:07:18 am

As a CNC Programmer / Machinist by trade, a Manufacturing Engineer and Industrial Engineer by education, a Facilities Engineer by occupation, and the owner of a 2011 Harrelson Bravura that I bought a few months ago - I appreciate your work, methods, research, and horns..Keep up the GREAT work!

Reply

Dave Wondra

5/7/2014 11:10:55 am

It is sometimes along the lines of "I want it, though don't want to pay that much, so I'll turn it into your problem instead of mine". In other words, I can rationalize not paying the price (and feel better about myself) by calling the item overpriced, low value, you'll get yours in time, whatever...

Reply

Bruce Bonnicksen

5/7/2014 12:43:41 pm

Jason,

Reply

Greg Zent

5/7/2014 01:53:49 pm

There are some very well written views here.

Reply

5/8/2014 03:04:11 am

Jason---I am really glad that you took the time to write a blog post on this very topic. What I see in your post goes far beyond the surface of a response to an ignorant person and cost vs. value. What I see is a great snapshot of your character and what you are really made of. In all of the master classes, consults, and presentations that I do I always want to make sure people get to understand your character, nature, and motivations. Your trumpets and products are not just a result of your innovation, hard work, and creativity---it is actually your character that comes through as well. I am thankful to be friends with you and to be partnering with you on this journey we are on (Also posted as a FB reply to post).

Reply

Marcus Pederson

5/8/2014 04:09:43 am

Thanks for the blog...I enjoy your writing, but you really do not need to justify yourself, your prices, or your horns...your work, inventiveness, and integrity do that already. Keep up the fight. Thanks for allowing me to own one of yours Summits

Reply

Anne McLaurin

5/8/2014 04:52:30 am

I can't wait to stop by your shop to check out those bottom caps! And pick up my G bugle! Love your writing Jason.

Reply

Ken Gardner

5/8/2014 11:42:36 am

Wow! This one sure got the HT'ers hackles up! I enjoyed this entry and comments very much.

Reply

John Baumchen

5/12/2014 01:21:48 pm

First let me say Jason I love your work, you idea's and your williness to share. 7 years ago you encouraged me to fix a trumpet myself and started me on my way. You have inspired me in many different ways.I embrace science, music and mathematics like children and can not separate any from the other's really.

Reply

Warren Lopicka

9/12/2014 05:02:45 am

Interesting blog and comments. I echo Greg Zent's, Dave Wondra James Knabe's comments. Jason provides quality products and stands behind each of them. You rarely find this in today's world. Doing business with him is refreshing. I wish I could work with him on a monthly basis.....imagine the horns I would have! Smiles. For those of you Harrelson horn owners .... Enjoy the day and time playing your horn. For those without a Harrelson horn....call Jason. Take care.

Reply

John

9/15/2014 05:45:39 pm

LOL....When I disagree with Jason it is not that I think I am write on the matter it just means I am not ready to agree with the truth he has already figured out. It is kind of like having an argument with God in that I can not like what he has to say on a given issue but not liking what he ahs to say does not make me correct.

Reply

8/18/2016 04:39:56 am

trumpets for all levels of players on offer with trumpets in all price ranges, with fast delivery.

Reply

Maurice

10/21/2020 05:02:35 pm

I did not know all this went into the process. You are a great! For sharing this and doing the work that you do.

Reply

Minimum Wage

10/26/2020 12:04:31 pm

The guy complaining that Jason charges too much should be told he should work for minimum wage because he is overpaid. Keep doing what you do Jason. I look forward to owning one of your horns one day.

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed