|

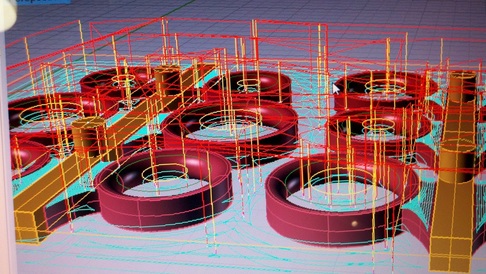

I recently discovered that I have 4 trumpet orders requiring cylindrical finger rings within the next two weeks. This is unusual as ergonomic finger rings are the most popular and I don't make the other types very often. Since I normally cut and finish every cylindrical finger ring by hand and I need 12 total, I did the math and found that my time would be better spent re-designing them to be cut on my vmc. However, this means I need to take the shapes in my head, draw them on the computer in a CAD program, then translate that into tool paths to be read by my vmc along with designing (or re-using) fixtures to hold the stock indexed on two opposite sides. The rings will be cut from one solid piece of 4x12x.25" stock that is then turned over and re-indexed accurate to .002" to cut the opposite side. This will reduce finishing time and accuracy overall making my life easier, my job less labor intensive and my parts of a more functional design and higher quality. But all of this takes time, patience and a lot of thinking through the entire process. If you've ever played chess, then you have some idea of what it takes to translate an idea into a finished piece of machined metal...you MUST think through the entire process. Make one mistake in programming/designing the entire process and you could very easily damage the stock, parts, machine or even you! A 15hp spindle motor running a 1/2" endmill at 6000 rpm with travels of over 1000 inches/minute that crashes into the machine could very easily damage all four in less than a second. So, unlike chess, I must be sure of every move before I ever turn the machine on. After doing this for many years, I'm certain my mind is forever changed. I tend to see consequences long before I ever do anything...not that I can do this in every aspect of life, but knowing all the parts of a project before you begin is very valuable. Of course I still make it up as I go as was the case with the original designs for many of my horns like the gravity, medusa, vines, mass, spectrum and dozens of other creations.  This may also offer some insight into wait times when I mention I'm designing a new idea/trumpet/accessory. A simple sheet of finger rings will probably eat up at least 12 hours of my undivided attention and these are very simple parts. Try designing a production process for the new SWE tuning slide and you're in the neighborhood of 180-200 hours before the prototype is ever cut or tested! Move into the realm of designing an entirely new instrument to be cut on a vmc (Elliptiphone is my current project) and you're looking at around 1000 hours minimum staring at a computer screen, measuring parts, checking volumes, tapers, wall thickness, machining scenarios, ordering custom tooling, designing and building custom fixtures and imagining the process to find errors and omissions before they ever happen. This could answer the all too often question people have asked me over the years, "If Standing Wave Efficiency is real, then why don't Bach or Yamaha redesign their horns to be more efficient?". Can you imagine how much longer and the expense involved for a major corporation to do all of this? It could cost them a fortune to research and develop something based on SWE, then the cost of re-tooling an entire mass production line, then branding and advertising the new designs. I have no doubt the cost would be in the millions. I have the advantage of understanding every step of the process so my 1000 hours to produce a new design is relatively quick and inexpensive. That is, if you disregard the 10 years of 80-hour weeks I put in to learning all of these things from square one. No matter how you see the problem, taking an idea through the machining process to a finished product is no simple task. If I could only clone myself! back to my work... Jason Here's a video (below) I produced for my family when I first started learning to use my latest VMC, this was a prototype setup, which after many months eventually became a full production process that is quite different today.

1 Comment

Luis

11/19/2011 01:38:32 pm

Hello:

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed