|

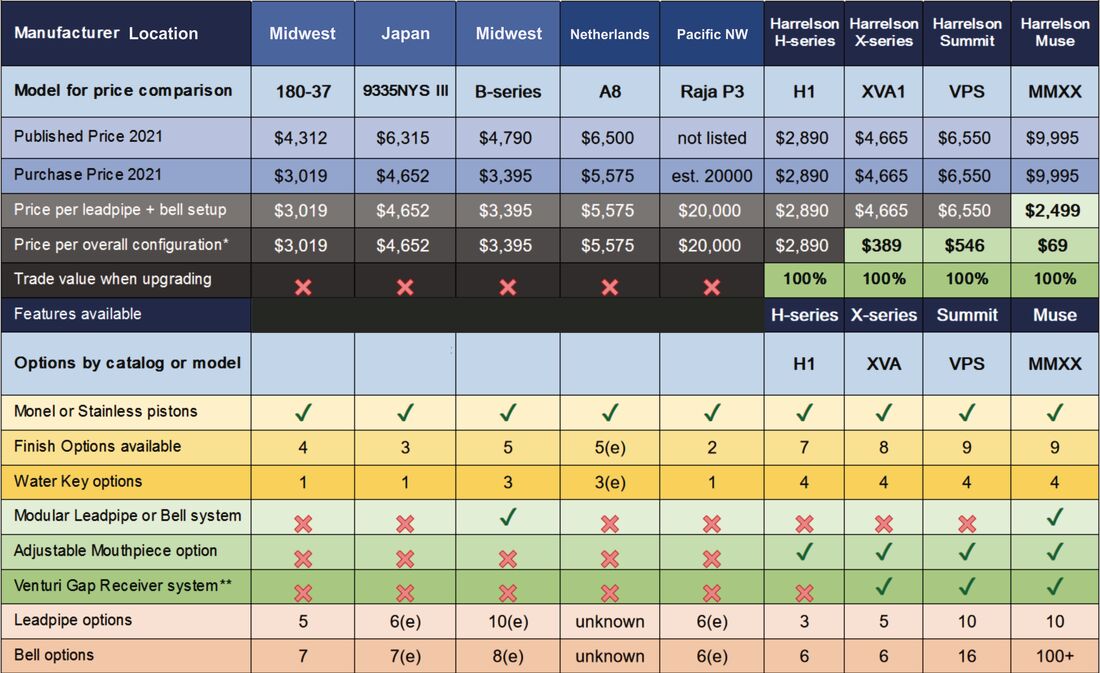

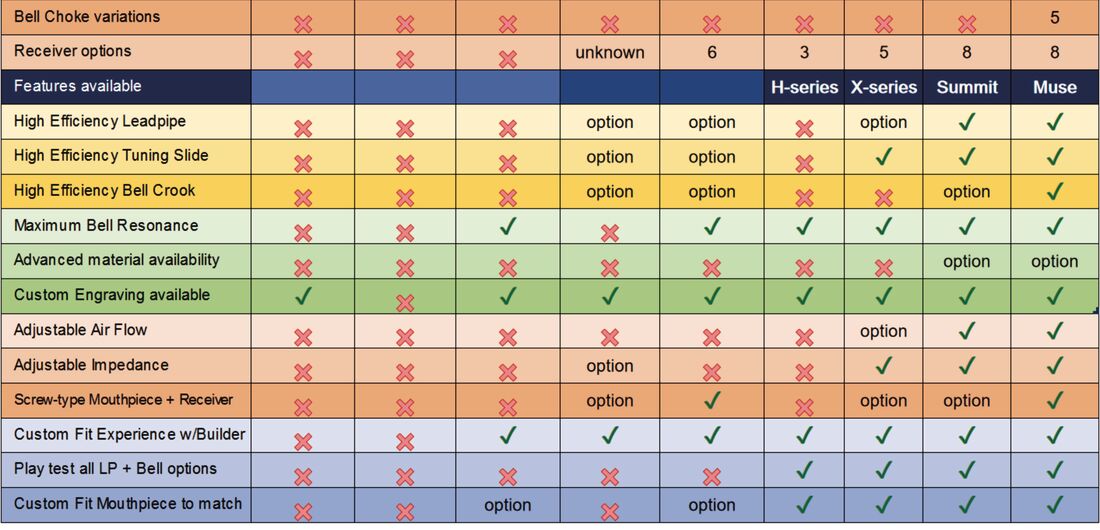

Most cutting edge technology was invented years or even decades before it became popular. Take the electric car for instance. The first working test car built by Robert Anderson was created in the 1830's. That's nearly 190 years ago and we're just now getting around to putting them into mass production. Why did the electric car take so long to catch on? Well, it required nearly sixty years of research and development for the first real electric car to go into production in the 1890's. So the answer to the 190-year-old question is that a lot of development of automobiles, batteries, software, computers, and much more was required. When I say a lot, I mean generations of scientists and entrepreneurs devoting their lives to this effort. And what about demand for the electric car? Did this exist before the hybrid Toyota Prius debuted in 1997? Was it Tesla Motors' Roadster launch in 2008 that got everyone excited? The demand for electric cars was barely present throughout most of those 190 years and many would argue that demand barely exists today. So what changed? I'll give you a hint, the answer is related to governments and the planet. I'll diverge for a second to note that putting millions of electric cars on the road today will only reinforce our need for more coal powered energy plants, which may be counterintuitive to... well, let's just move on. Now consider all of the great innovations that have come about on the trumpet over the past several hundred years. There are many origin theories so let's just choose one. How about the theory that trumpets were used to communicate the commencement of battles, hunts, and ceremonies two to three thousand years ago. The first innovation was likely the use of bronze and brass. What happened next is anybody's guess, but it involved a lot of people trying a lot of different ideas. There were open holes, then keys, and finally various valves to change pitch sometimes by adding tubing, but not always. We eventually settled on piston (Perinet) valves and rotary valves (1830's) still common on french horn and many other brass instruments in Europe. Innovations throughout the mid and late 1800's mostly included creating brass instruments in a wide variety of pitches and ranges from tuba to cornet to piccolo trumpet. The early 1900's saw the trend shift from wide-tapered-bell rotary trumpets and flugelhorns to cornets as they became one of the world's most popular instruments along with violin and piano. With the introduction of live radio, we soon saw cornets stretch into a longer, thinner instrument often known now as the pea shooter. This was really a cornet trumpet hybrid designed with a smaller, more narrow-tapered bell to project into microphones and out to live audiences in dance halls. The Big Band era saw a full shift to the basic trumpet design we know and play today. There were some very interesting and notable experiments throughout the 40's and 50's that most trumpet players do not remember. The Wohlrab trumpet with one or all three slides moved to an internal piston/tube design. High efficiency bracing systems from Holton and Huttl were complemented by high efficiency mouthpiece body designs by many manufacturers including Olds, Conn, Holton and others. Fast forward to the 80's and you'll see both Monette and Bach essentially copying these mouthpiece body designs (even the rims) to launch a new era of "innovation". Heavy bracing became a fad in the 90's and remains a quirky, yet prized innovation today, but this is where things start to get strange. I became a student of brass acoustics in 1992 thanks to an experience that changed my perspective for life. In short, I handed my 1960's Bach Strad to my friend, who handed me his brand new Bach Strad and we compared instruments. His trumpet played hands down better despite being the same make and model. If you want to know the entire story, check out my blog entry on this subject and Standing Wave Efficiency. In 1992, my goal was to make my Bach play like a new Bach by adding weight. There was a lot of talk about how weight made trumpets darker and better, but I really didn't know what that meant at the time. I made a custom set of heavy bottom caps and sure enough my trumpet was more stable on some partials, but the oscilloscope showed no change in tone color. This blew my mind at the time so I made heavy top caps and they also helped. Next was heavy finger buttons, which did make a small difference on one partial, but nothing exciting. It wasn't until a year or more later that I finally added heavy bracing to my Bach and the results were...mixed. I liked it and I didn't like it. Some notes played much easier than other trumpets, even better than new Bach Strads. But many notes were still very problematic and the trumpet became more difficult to play than when I started. It was like playing a piano where only 1 out of 3 keys was working properly. Fast forward to 1994 when I had really started to dive into the acoustics literature and fully understand the energy within anti-nodes. I soon realized that the nodes and antinodes are fluid, they move around as you play different pitches and slip up and down based on the tuning slide. I had a breakthrough when I discovered that heavily braced trumpets were more of a marketing gimmick than a true innovation. I had been convinced for 3 or 4 years that those really expensive trumpets in 24k gold with cut-outs and bracing everywhere were the holy grail. Now I was left with the realization that what you see is not always what you get. Bracing is important, but it rarely provides the results that most people claim to be true. It turns out that heavy bracing was not much of a useful innovation, which is why it is not included on my trumpet feature comparison chart. However, the placement, size, and shape of bracing is in fact very important. More bracing is not necessarily better. More weight is definitely not better when generalized with a measurement on a scale. I have likely invested more time and energy experimenting with bracing designs than perhaps anyone in history. Having built hundreds of different trumpets, each with their own unique approach to bracing revealed my ignorance, often based on common trumpet mythology. Like the heavy bracing myth, there have been many innovations that eventually did not translate into lasting, useful solutions. The A/Bb tuning crook, adjustable micro tuning slide, Jerwin variable cup mouthpiece, reverse tuning slide, acousticoil inserts, slide-less pistons, cryogenic treatment, clocking the mouthpiece, and wooden tone boosters are all examples of innovations that either didn't work well or did not catch on. And there were amazing ideas that should be in production today that simply didn't gain traction. The pitch finder is one of many examples of technological advancements that worked well, but didn't stand the test of time, at least within the perspective of today's market. I have not scratched the surface on the true number of innovations that were, at some point in time, introduced on brass instruments as that would be an entire book. But I would like to discuss the most useful innovations that were not derived directly from effective marketing. We will not discuss hand hammered bells, reverse leadpipes, round tuning slides, heavy bottom caps, and the like as these innovations pale in comparison to the technological wonders that exist today. 1) High Quality Pistons & Casings

This may seem obvious and unimportant to us today as nearly all manufacturers offer great valve action, durability, and reliability. But before any of us were born, some brass instruments were made with wooden pistons. Others were made from copper, bronze, brass, and other alloys with or without a hard plate of nickel. The metallurgy required to create a high quality piston and casing is more complex than you may realize and we should appreciate this great innovation regardless of how commonplace it is today. 2) Finish While the original finish of the earliest brass instruments was in fact raw brass, the most common finish today is polished silver. We have grown to love or hate (I personally like all finishes) the mirror-like silver that coats most of our trumpets, but there is a price to pay in terms of upkeep and wear. Silver is soft and will wear relatively quickly while tarnishing daily. Brass is more durable, but can also degrade as acids in our hands and saliva erode the zinc within the alloy sometimes causing pitting and brittleness. Newer finishes include powder coats, which are very durable, but require a special application and thus far Harrelson trumpets have never used powder coat technology. This primarily due to the fact that it would essentially make the trumpet plastic coated and reduce resonance. Other finishes now include Acoustic Armour, which is a two part epoxy combined with metal and ceramic dust baked onto the brass surface. AA provides a long lasting, durable finish that can look like real metal with depth in the right light. Another finish that was likely pioneered by Taylor Trumpets is automotive enamel. While Andy sends all of his work out for painting, these finishes can be just as hard or harder than Acoustic Armour offering amazing beauty and durability. I am currently upgrading our spray booth and oven to accommodate enamel finishes that will likely go into production in 2022. 3) Water Keys This is another innovation we take for granted today. The lever water key is the traditional option on most trumpets followed by the Amado (push button cylinder). Both have issues with reliability and air leaking. Grab a paper clip and bubble gum if you're relying on either of these designs because your days of reliability are numbered. The newer Joy key is an interesting innovation designed by Andrew Joy. This design allows air and water to escape through tiny filtration balls like in an aquarium aeration system. Another innovation is the Saturn water key invented by Denis Wedgwood. This system relies on a simple stainless steel ball to seal the hold offering extreme reliability and ease of use. 4) Modular Leadpipe and Bell systems Modular leadpipe and bell systems are nothing new, but the ways in which they have been innovated in the past 5 years offers more flexibility, reliability, and efficiency than ever before. Schilke trumpets have long offered modular and tunable bells, but these tend to bend and break with use. These are great for resonance, but require extra care. Getzen/Edwards has also offered a similar system, but with modular leadpipes that slide into a tube and screw in place. One of my favorite systems created to date is credited to Will Spencer, who also makes beautiful trumpets. The Spencer modular system can be adapted to almost any leadpipe and bell. Maximum Bell Resonance and Standing Wave Efficiency were the top two priorities when I designed the Muse Modular trumpet design that currently offers 10 modular leadpipes with 40 interchangeable segments allowing you to create your own custom leadpipe. And, the modular bell side of the Muse offers 16 standard variations with dozens more in prototyping including examples fully CNC machined, laser sintered, 3d printed, and hand hammered from brass, bronze, aluminum, copper, stainless steel, and titanium. The Muse system also offers the option of removing a bell from any trumpet and fitting it to the system allowing the player to change to any bell that has ever existed in just a few seconds. 5) Adjustable Mouthpieces The concept of an adjustable mouthpiece likely dates to sometime between WWI and WWII, though I cannot find an exact date. I personally own dozens of examples of adjustable and modular mouthpieces as I've thoroughly researched this topic over the years in preparation for my own 5MM system introduced in 2011. There are very few trumpet manufacturers offering modular mouthpieces as most of the market is represented by custom mouthpiece makers. Terry Warburton makes an excellent system that offers a wide variety of "tops" (rim/cup segment) and backbores that include the throat segment. The advantage of a modular mouthpiece design becomes obvious the first time you ask to try Rim X with Cup Y while changing the throat diameter independently of the backbore. The 5MM system may be the only mouthpiece on the market offering this advantage. 6) Leadpipe tapers Every leadpipe is made to a specific taper. Well, that's the hope! Not all leadpipes are created equally so the accuracy and effectiveness of this theory gets put to the test with many of the inexpensive imports on the market today. But the major manufacturers like Selmer Bach, Yamaha, Schilke, Getzen, and many others have a library of as many as a dozen different leadpipe mandrels with which they create their library of models. A trumpet marketed towards lead and commercial players will often feature a small venturi (the inside diameter of the leadpipe entrance) and a relatively small exit diameter to create more sizzle and resistance suited for upper register playing. This is not always the case, but often times we see smaller leadpipes for high note playing and larger variations for bigger Jazz combo or Orchestral playing. The Harrelson leadpipe options include drawn tubes, which are made with the same process as most manufacturers. And fully CNC machined high efficiency variations that allow undercuts, varying segmented rates of taper, higher accuracy, thicker walls that resist antinodal transfer of energy and prevent red rot over a very long life. 7) Bell tapers Like leadpipes, bell tapers and diameters have an effect on the tonal character of the instrument. The easiest way to visualize this in basic terms is to picture a piccolo trumpet bell taper and compare that to the taper (and tonal character) of a flugelhorn. There are hundreds of bell variations, but the vast majority of all professional trumpets sold today are made with tiny variations of just three tapers. David Monette should be credited for stretching our ears with a wide array of tapers and diameters that likely did not exist before he put his creative mind to work. In addition, Monette exploited annealing and new bell thickness variations that forever changed the landscape of what is possible in the brass world. 8) Bell Chokes This innovation is not new, but has been pushed to the wayside for many years. Some manufacturers are using bell choke technology to create more sizzle and zing in their lead/commercial models, but do not advertise this fact. Perhaps this is to protect market share? Regardless, the earliest piston valve trumpets sometimes used bell chokes. The concept is loosely defined as exchanging some segment of tubing within the bell tail with a inner diameter different than the bore size, often using smaller tubing. This creates a distortion type effect on the far end of the scale and more vibrancy on the other. The Muse Modular trumpet offers interchangeable bell chokes in five variations. 9) Receivers The topic of mouthpiece receivers is riddled with examples of good marketing that produces very little in terms of added functionality. Thin receivers easily transfer sound wave energy into vibration, thus robbing your hard earned standing wave of amplitude and stability. Thicker receivers prevent this problem at the expense of added weight. 10) High Efficiency Design This is an innovation that has completely revolutionized trumpet design in the past thirty years. Despite the fact that a fair portion of this "innovation" was explored throughout the history of the trumpet, especially in the 50's and 60's, the true results were not realized until the late 1990's by just a handful of makers. I recall exhibiting my instruments at a conference in the early 2000's and getting lots of strange comments about weight, bracing design, thick leadpipes, tuning slides, and so on. One group of French-speaking men came over and picked up my trumpets, giggled, took photos with all of our inventory and walked away. Later that day, another vendor informed me that they were important figures from Selmer. The following year we saw the introduction of the Selmer Concept TT model, which featured a new leadpipe that looked much like my original Muse trumpet leadpipe design. I got one and disassembled it only to discover that Selmer had soldered a hollow tube over the top of an existing leadpipe. After some testing on the spectrum analyzer, I confirmed that the SWE value was very low on almost every partial as the antinodal energy was transferring much more energy into vibration of the leadpipe than the original drawn leadpipe design. Several other manufacturers followed suit making hollow twin tube designs, which again resulted in instruments that were more difficult to play. The other negative experience that has been shared by many twin tube leadpipe design owners has been the sound of metal rattling inside. What Conn-Selmer and others didn't know was that the Muse leadpipe was solid lead fill between a brass drawn leadpipe and outer tube. This tiny detail made all the difference in the world. Nearly every component of Harrelson trumpets are designed from the ground up to offer the highest SWE values possible while maintaining Maximum Bell Resonance. These are the golden rules I live by when designing models like the X-series, Summit, and Muse. The exception is the H-series which is more like a standard design with added efficiency where possible within the constraints of a lower production price point. My original approach to fabricating high efficiency leadpipes, crooks, bells, etc. was to bend thick tubing. However, despite consulting specialists throughout the tube bending industry, we could not find a way to bend thick brass tubing without creating a porous inner and outer surface that would require further metal removal to correct. If left porous and in a soft annealed state, the metal would be prone to attack by acid leaching the zinc away eventually causing red rot. The other concern was that dents cannot be repaired. After exploring casting, laser sintering, and hydroforming (and years of trial and error), I finally turned to CNC machining. Nearly 20 years after purchasing my first CNC machine, we are now home to some of the most unique custom CNC mill and lathe production equipment in the United States. We don't have the most expensive machines, but they are very good and specifically modified to perform to higher standards than any of our previously explored techniques mentioned above. By machining entire tubes, tuning sides, bell crooks, bells, and valve casings from solid material, we can control factors to a higher degree while producing a more efficient and more accurate component. We have invested over a million dollars into machinery, software, tooling, and time into creating the most advanced trumpet production process today. The goal has always been to produce the most responsive instrument possible while increasing overall resonance. 11) Maximum Bell Resonance Speaking of resonance, this is one area that must be done correctly or the entire system will fail. Bell resonance is more important than efficiency, as Yamaha has clearly demonstrated. Schilke, Yamaha, Monette, and many others have devoted countless hours to achieving maximum bell resonance. When the standing wave can set the bell material into a repetitive motion that accentuates the original wave, we have something very special. To put it kindly, not all manufacturers make this achievement their goal. 12) Advanced Materials This is new territory for most manufacturers and will likely be explored by a select few. Schilke experimented with various materials, which was followed by Dan Parker and the crystal bell. Then you have the DaCarbo carbon fiber bell, which is an awesome use of advanced materials. At Harrelson, we are actively exploring the following materials throughout the trumpet including the bell; Aluminum, Stainless Steel, stabilized and natural Hardwoods, Tegris, Delrin, Titanium, Nylon, Carbon Fiber, Fiberglass, and Damascus Steel. Some of these are theoretically better than brass in terms of overall resonance and efficiency while others may reduce weight. Our goal is to approach a one pound Muse trumpet over the course of the next ten years and a sub-one pound fixed trumpet within 4 years. 13) Adjustable Air Flow This innovation is relatively unknown as Harrelson is the only manufacturer offering an adjustable venturi system available on both our instruments and as an upgrade to most other trumpets. The VGR system, Venturi Gap Receiver, is essentially a modular leadpipe system that works by changing the entrance to the leadpipe with precision machined attachments called inserts. You can make any trumpet fitted with the VGR feel as small or as large as you like within just a few seconds. This opens up an entirely new world of possibilities. This first five minutes playing a VGR equipped trumpet will blow your mind. Most of us having issues playing specific notes or partials will find that adjusting the venturi is often most, if not all, of the solution. 14) Adjustable Impedance This is the other half of the VGR system, but rather than adjusting the venturi, you adjust the impedance change value. This translates to making the trumpet feel more flexible between partials or the opposite, making them feel more centered and locked in. The VGR system offers 96 variations of inserts to fine tune the feeling of resistance, both in terms of impedance and air flow. If you have yet to experience this technology, you need to visit us in Denver, Colorado. 15) Screw-type Mouthpiece + Receiver systems I do not recall the first time I saw a screw-in mouthpiece as my memory is deep rooted in my own experience. My early mouthpieces were designed with a screw system that customers could not see as it was inside the mouthpiece assembly. These were introduced in approximately 2002, which may be my first introduction to the concept. I do know that in 2002 through 2010, we offered integral mouthpieces that were not removable and this concept upset a lot of people. What if you need to change mouthpieces was usually the question, but clients buying these integral systems were set on their size, for life. As I developed my 3-piece mouthpiece system into the current 5-piece (5MM is short for five piece Modular Mouthpiece), I started making prototype screw-in mouthpiece bodies that included the VGR system. We now offer these for our clients on a limited basis, but they will become a full scale production offering in 2022. This may be the first screw-in mouthpiece to trumpet design put into production as it pre-dates the Monette, Adams, and AR Resonance designs. I've often wondered if my VGR system was the inspiration of other makers to follow this path much like Conn-Selmer sought to produce their twin tube leadpipe. Regardless, a screw-type mouthpiece and receiver system is only as effective as the underlying engineering goals. If you cannot adjust air flow, flexibility, slotting, impedance, and resonance, then the system is simply a mouthpiece that screws into a receiver. With that said, AR Resonance is one of my favorite trumpet companies on the planet! 16) Custom Fit Experiences It's so great to see manufacturers work with their customers, the musicians who create so much beauty in our world. Almost every small manufacturer offers this service. The big boys don't care because their customers probably don't care either. Every trumpet player wants more or less out of their trumpet experience depending on the person. I spend many of my days working directly with my clients in our showroom, machine shop, and remotely to assist in designing and building the vision of each individual artisan. 17) Play Testing every option It's nice to read specifications on a chart and to hear others playing the trumpet model you may want to someday own. But what about testing all the options to see what works best for you? After all, you are not the person performing in the video demonstration and words on a page may not translate into what fits your skills, physiology, approach, etc. At Harrelson, you can play test every single combination of leadpipe, bell, tuning slide, air flow/impedance setting, with any mouthpiece ever conceived in one session. Our Muse Modular trumpet was specifically designed to offer every variation and can be configured to any variation in approximately 90 seconds. 18) Custom Fit Mouthpieces There are three primary components to any brass instrument. The player, the instrument, and the interface between the two known as the mouthpiece. Harrelson has over 20 years of experience fitting thousands of professional trumpet players to the mouthpiece variations that meet their needs creating the perfect interface between your body and instrument. 19) Trade Value - Upgrading Equipment All Harrelson trumpets are eligible for up to 100% trade value when upgrading to a new Harrelson model trumpet within five years of purchase. You can start with a $3300 H-series and trade up to an X-series a year later. And you can then take that X-series trumpet and upgrade to VPS Summit or Muse only paying the difference. Limitations may apply depending on the overall condition of your instrument at time of trade.

2 Comments

Ithiel Torres

9/25/2021 05:48:27 pm

The reality is, that when I first heard of Harrelson Trumpets and their products, I was very skeptical and thought that there were many gimmicks. Nevertheless I gave it a try, beginning with a 5 MM and to my pleasant surprise the mouthpiece is better than expected. My endurance, slotting, tone and locking notes is better than ever. I am a 68 years old trumpet player that started playing when I was 12 just like many kids, in school band. Today, I’ve had the privilege to play in many countries in Central, South and North America as well. Not to mention Europe and the Caribbean. Next “gimmick I tried was the HEVS, Again I personally thought it was a Jason’s gimmick to make money especially during the heat of the COVID-19 pandemic. I was for a rude awakening when I got them and installed them in my beautiful Phaeton Las Vegas fluegelhorn. My valves now are more efficient, faster and reliable than ever. So it was not a gimmick at all. Is a real solution to many common problems that many of us trumpet player go through everyday.

Reply

Jerry Doerksen

9/26/2021 08:39:23 am

Thanks for this review of various aspects of trumpet design and manufacturing. I've been to your shop in Denver and was able to see one of your milling machines in action. I'm an old guy who plays trumpet in a community band but I've always been a "dabbler" who, when something breaks or is not performing to expectations, tries to make it better. So, I appreciate your curious mind, the drive to determine the "why" of things, and your zeal for innovation. Over the years of dabbling with many different brands of trumpets and cornets, I've acquired many different brands and sizes of mouthpieces and found the differences in sound and ease of playing these mouthpieces make to be quite remarkable. Most recreational players don't have the opportunity to try out three dozen or so mouthpieces to find one that is best for them. Some players I know still use the same mouthpiece they had in high school because it's the one their band director recommended, say a Bach 7C. At any rate, it's all very fascinating. Keep up the good work.

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed