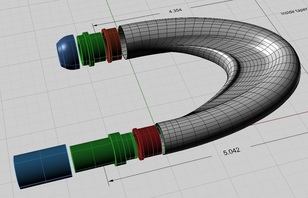

A fair number of people make comments that have me scratching my head. Like this one, "It must be nice to have those expensive CNC machines that will make whatever you want." In reality, my CNC machinery will do exactly what I program it to do. There is far more to building trumpets than pressing a few buttons! This is somewhat related to another comment I have heard hundreds of times, "If you know so much about brass acoustics, why haven't you published your findings in any scientific journals?" I could literally write numerous volumes of information, instructions, guidelines, rules, tips and tricks on running CNC machines alone. And I could write even more about entrepreneurship, communications, psychology, brass acoustics, manual machining, fabrication, engineering, aesthetic design, brass pedagogy, musicianship and the topic of minding your own business. But wouldn't you rather have the fruit of my labor rather than my knowledge? Who wants to read all those books that I could potentially write when I could be building instruments? So let's leave it at this... Yes, I have done my homework. Yes, there is much more to designing and building trumpets than you may imagine. And yes, you are welcome to visit either of my shops to get a glimpse of the process first-hand. An no, there is no team of little elves doing the work for me. Jen, Christine, Kate, James and I do all of the work ourselves. And craftsmen like Tom Green and the staff at Anderson Plating assist us in the final finish. Our team is small, our integrity is high and our results are second to none. Want a glimpse into the magic of CNC machining set to some of my own free improvisation? You're in luck! This video shows the final stages of a custom tuning slide being machined on our VMC.

6 Comments

Josh Warner

9/16/2015 07:05:19 pm

The upper left screenshot on this blog post is interesting - I don't think it's a tuning slide. Are you teasing the SWE bell crook to see if we're paying attention, Jason?

Reply

9/17/2015 06:50:35 am

I can attest to what Jason says here. I met him in 2013 at the ITG Conference... I was completely blown away by the sound of his horns. Later that year I visited his shop... bought one of his proto-type trumpets that day and ordered another! I now have a Summit One, Summit Midnight and a custom C trumpet and yes he is still building more for me. We are having our second Harrelson Clinic in Detroit (Oct 8 - 10). I love learning knowledge from Jason, but in the end I am even happier that he has such great knowledge and craftsmanship skills... so I can enjoy the fruits of his labor! Thanks Jason!

Reply

3/13/2020 01:31:06 am

Hey there, first of all thank you so much for this post and honestly I was searching for the same information from last few days. Keep posting and keep sharing..

Reply

8/11/2020 06:49:07 am

Thought I’d throw up a second post relating to Jason’s work in the trumpet field. When I met Jason in 2013, he showed me pictures and talked about his future concepts of building his trumpets. Well today Aug 2020, many of those concepts are reality. It’s truly amazing to watch this process happen. What even more amazing, is the results... his horn are getting more efficient and make playing easier. Result... you can focus more on playing music!’ Thanks Jason and team!

Reply

I like that you pointed out that the CNC machines can follow the operator's exact program. I can imagine how helpful that would be to ensure that the job will be done in no time. It can be beneficial to small businesses to have partnerships with industries that offer this to meet clients' expectation and further expand their reach to have more clients and orders.

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed