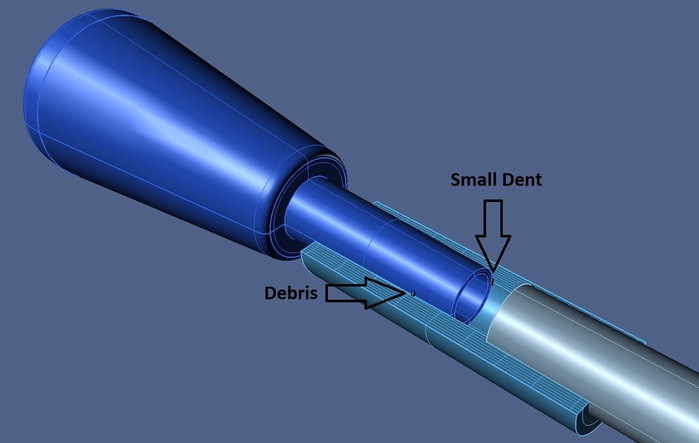

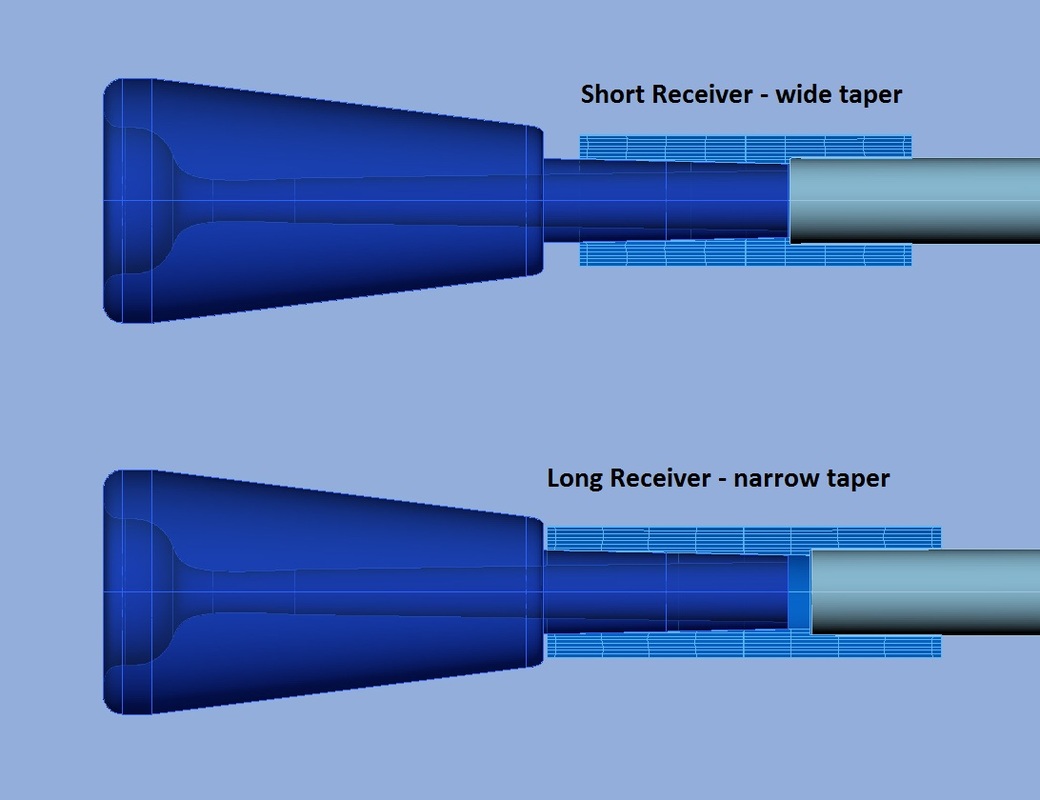

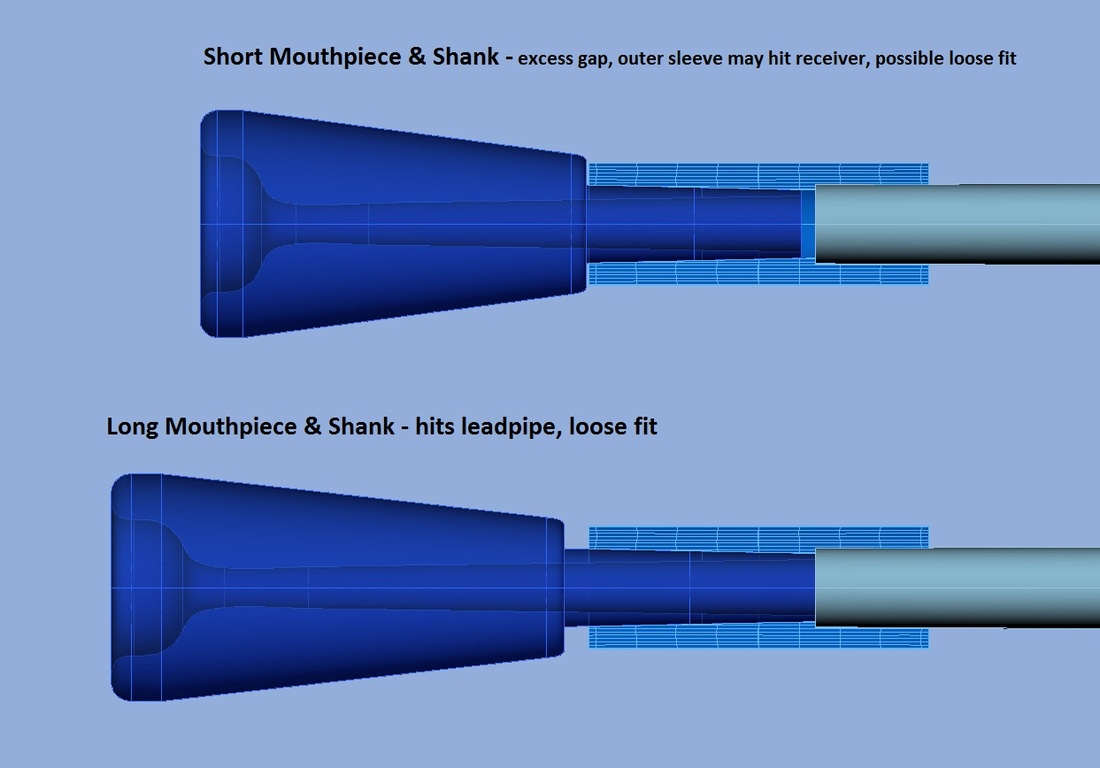

In Part I of Achieving Optimum Mouthpiece Gap, I defined gap as the space measured from the end of the mouthpiece to the beginning of the leadpipe. I also explained how this usually affects playability for most players. You may want to read Part I first as this will be helpful in understanding the following illustrations and explanation. Next, I will examine the various causes of mouthpiece gap inconsistency and then offer solutions to compensate by physically changing the length of the gap. I will also offer guidelines to better understanding which gap setting may best fit your playing preferences. What causes Gap variations? In the illustration to the right, the top half of the receiver has been cut away for easier viewing. There are two very small pieces of debris between the mouthpiece shank and receiver, which may represent dirt, small dents or or manufacturing defects. Such obstacles are likely present in almost all mouthpiece shank to receiver setups and these change the gap considerably. The slightest debris or raised area on the tapered shank mating surface will increase gap. This means that a perfectly new mouthpiece and receiver could have defects that widen the gap. Debris and damage will also increase gap and could accumulate over time compounding the problem. Since optimum mouthpiece gap is our goal, we want to minimize these factors to maintain consistency over any period of time. What is an Adjustable Gap Receiver (AGR)? As mentioned in Part I, an Adjustable Gap Receiver (AGR) would solve these problems while giving the player complete flexibility in experimenting with various gap settings. And since the AGR is adjustable, anyone could set any mouthpiece to their individual optimum gap length. I have designed several different AGR systems utilizing the following mechanisms; 60 degree pitch screws, Acme screws and cylindrical shank collet chucks. The Collet System has proven to be the most efficient and versatile, yet the most expensive to produce. Later this year, I will redesign the Summit to include an AGR to solve all of the problems I have discussed. Why are manufacturers to blame for Mouthpiece Gap inconsistencies? The primary cause of inconsistent mouthpiece Gap is trumpet and mouthpiece manufacturers. There is no common set of standards by which manufacturers conform to produce consistent components in the brass instrument industry. In most cases, individual manufacturers focus on producing mouthpieces that fit their in-house brand(s) of instruments. Individual mouthpiece makers are then challenged with producing tapered shanks that fit most brand trumpets. However, this is surely a lose-lose scenario as the wide variance in mouthpiece receiver tapers is such that there can be no successful compromise between all brands. There will always be mouthpieces made to the highest quality and specifications that will not properly fit instruments of equal or greater quality. In fact, the odds are not in favor of the two variables producing an appropriate match to your gap preferences. Examples of manufacturing variables that contribute to Mouthpiece Gap inconsistencies.

How do I measure Mouthpiece Gap? Measuring mouthpiece Gap is fairly simple using a fine tip marker and a toothpick as outlined on my website here: Measuring Mouthpiece Gap I encourage you to take a few minutes to read my first blog entry on this subject found on the same link. Understanding how and why mouthpiece Gap is important could lead to better flexibility, easier wide interval slurring and attacks, improved accuracy, range and endurance. Is there a chance I will experience Mouthpiece Gap issues? It is common to have a mixture of these scenarios such as playing a Monette mouthpiece with a short shank coupled with a long receiver producing an extremely wide gap. When I hear of people trying a new brand of mouthpiece that didn't work for them, I first question if it was the mouthpiece or the unfortunate combination of manufacturing variables that is to blame for their negative experience. The odds are that mouthpiece gap is the primary factor by which most trumpet players choose their favored brand(s) of mouthpieces. If you don't think you have ever experienced a gap issue based on differences in manufacturing specifications and variations, try measuring gap differences with any of the following comparisons;

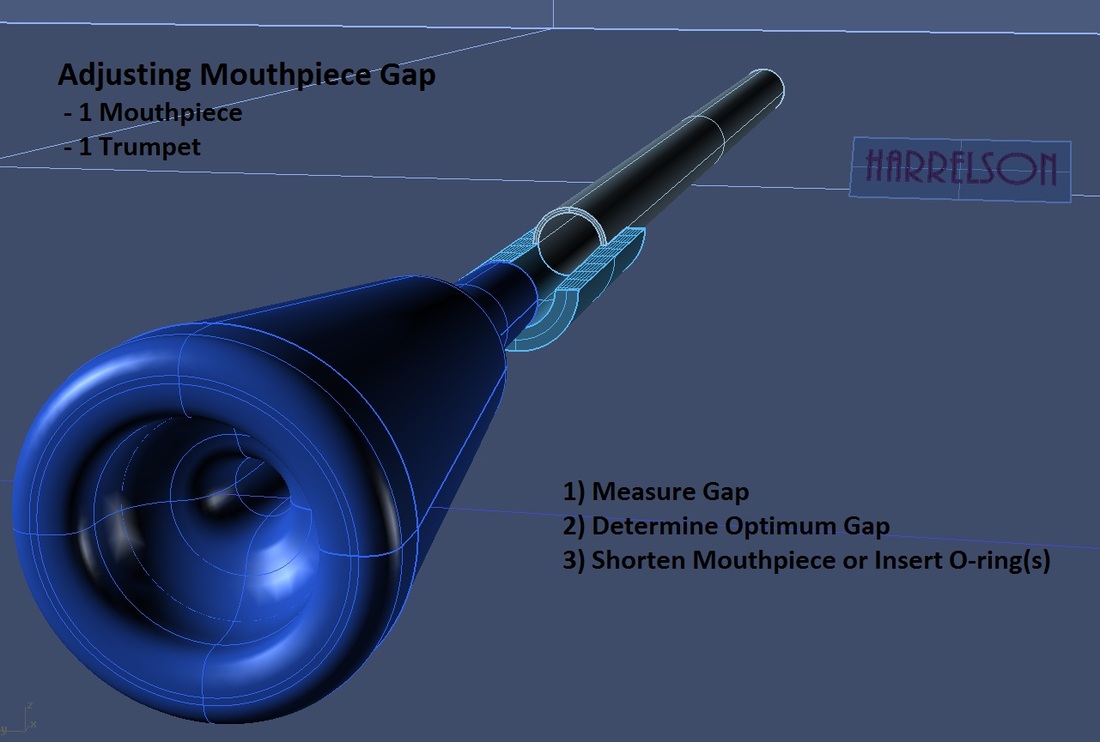

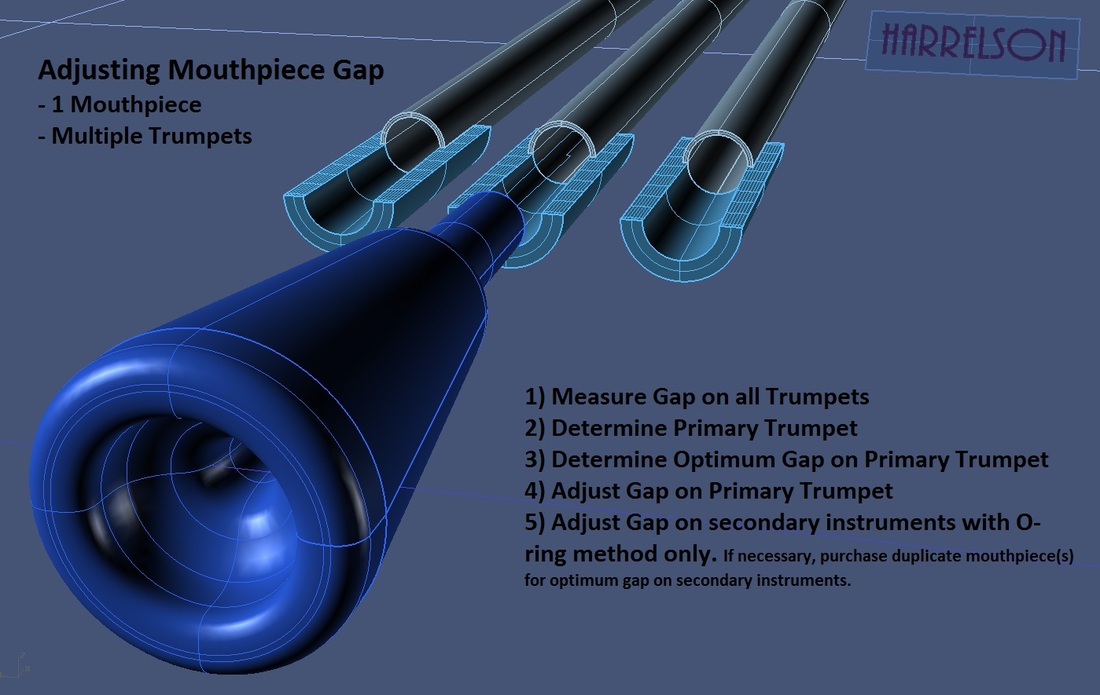

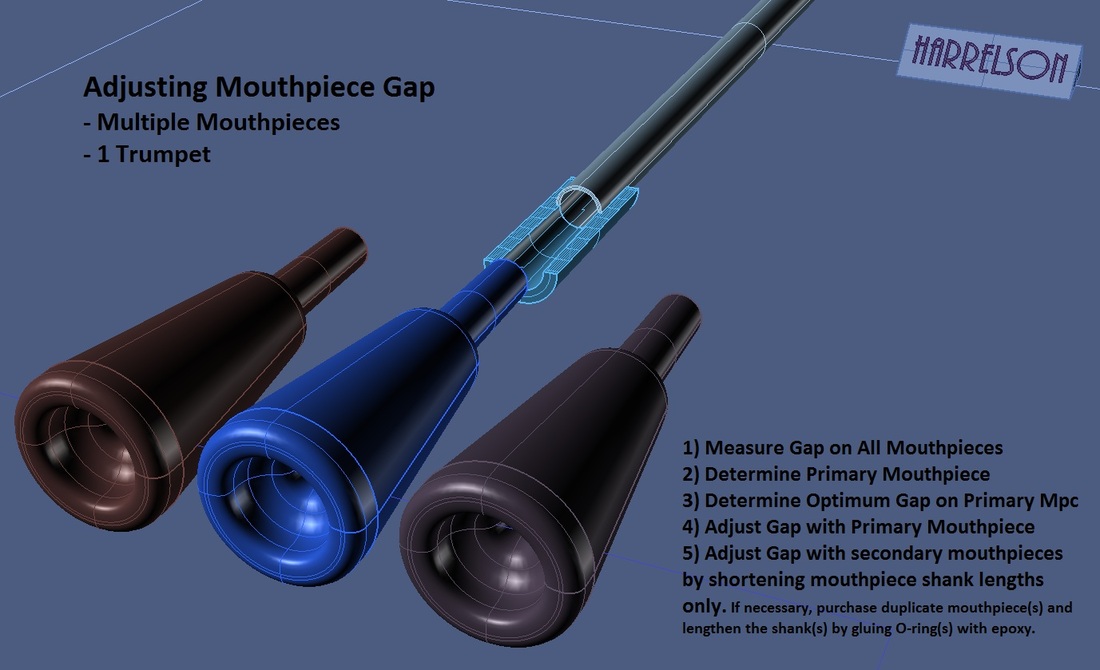

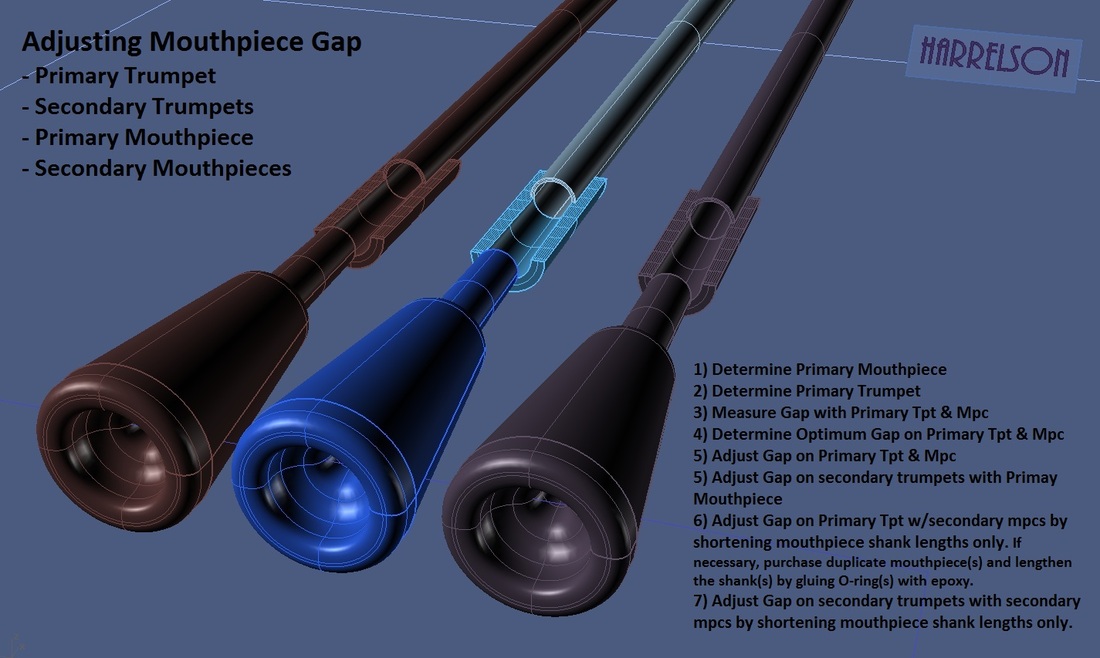

When designing and building trumpets, I set the optimum gap to the brand and size of mouthpiece each client will use on that horn. If a client wishes to play a Schilke or Monette with other brand mouthpieces on the same horn, I usually need to adjust one of the mouthpieces or find a compromise. It is impossible to compromise between two extremes such as sharing one horn with Schilke and Monette mouthpieces as the length variance is too great. How to adjust Mouthpiece Gap at home with a few simple techniques Now to the fun part, adjusting mouthpiece gap at home with your own two hands! The first step is determining your current mouthpiece gap with each mouthpiece you intend to use on a specific trumpet. If you play with the same mouthpiece all of the time, this will be easy. In cases of using multiple mouthpieces on one or multiple horns, there may be some additional challenges, but nothing too difficult to overcome with a few extra steps. I've broken each scenario down into steps for clarity. Please do not attempt to skip any steps or make assumptions as short cuts will compromise the validity of this process. I explain how to reduce gap and how to shorten mouthpiece after the following illustrations. How to minimize Mouthpiece Gap with O-rings

When your current Gap setting is too wide, usually over .120", it may be necessary to lengthen the mouthpiece shank or minimize space inside the receiver. This is normally achieved in a shop with tooling that widens the receiver taper. However, this is impractical for the average professional trumpet player and usually reserved for permanent changes performed by a trained technician. The simplest solution is to purchase a Mouthpiece Gap Shim Kit from Harrelson Trumpets, which are available in delrin or brass as a set that includes many sizes of shims that may be used alone or in combinations to achieve multiple sizes. Or simply purchase Nitrile O-rings at your local hardware store. Take your mouthpiece to the hardware store and request the gasket and O-ring bins usually found in the plumbing department. Select several O-rings of the same or larger inside diameter of your leadpipe venturi and the same or slightly smaller outside diameter of the shank end of your mouthpiece. Most leadpipe venturi range in size from .338 to .355 inches so you do not want an O-ring measuring any smaller than this size range. Once you have your O-rings, determine how much space you would like to fill to achieve Optimum Gap and carefully press them into place by inserting partially into the receiver followed by inserting your mouthpiece. Look inside the receiver to ensure a proper fit then test your horn with the new Gap setting. What has changed? Are wide interval slurs easier or more difficult? Do notes lock in too tight or not tight enough? Check your results against the illustrations outlined in Part I of this topic and make adjustments as necessary. In some cases, it may not be practical to insert O-rings into the receiver. This is true when you are setting the Gap of a secondary mouthpiece that measures too wide. This will require some creativity and patience as you will need to add the O-ring or shim to the end of the mouthpiece shank. The simplest way is to stand your mouthpiece with the shank end up. Now carefully epoxy the O-ring(s) to the end of the shank with a high quality ($5) 2-part epoxy. Wear gloves as epoxy is messy until it is cured, usually after 24 hours. Take your time positioning the O-ring(s) and check on it just before the epoxy sets. You can find the "set" time of epoxy in the instructions. Do not touch until the full curing time has passed or you may need to start over. How to increase Mouthpiece Gap by shortening the Mouthpiece When your current Gap setting is too narrow, usually under .080", it may be necessary to shorten the length of the mouthpiece shank. This may sound slightly insane, but believe me when I say most mouthpiece can be shortened a bit with little or no adverse effects. In almost all cases, achieving Optimum Gap is more important and beneficial than the small changes experienced by shortening the mouthpiece. With that said, I do not recommend shortening any mouthpiece more than 3/16". If you are using a digital caliper for measurements, this is around .190". If the mouthpiece needs to be shortened more than this amount, consider a new mouthpiece, new receiver or new trumpet. The best way to shorten the shank end of a trumpet mouthpiece is to simply chuck it into a lathe that has been fit with custom jaws forming a perfectly round grip slightly smaller than the outside diameter of the mouthpiece. Outside of a few shops in the world, you are unlikely to find anyone with a lathe setup to trim mouthpieces. So what's the second best way to shorten your mouthpiece? With a hand file and a deburring tool. Mark the length you believe needs to be removed. Now mark half of that length and file the mouthpiece down to this first line. Debur very lightly with a standard tubing bevel tool (found at the hardware store for $3) and play test the mouthpiece with the wider Gap setting. What has changed? Are wide interval slurs easier or more difficult? Do notes lock in too tight or not tight enough? Check your results against the illustrations outlined in Part I of this topic and make adjustments as necessary. If necessary, continue filing down to the second line or a new mark if you have determined some other setting would be beneficial. Always test after removing half of your goal as it is very possible you could create too much Gap, which is counter-productive. Remember, measure twice and file once. You cannot easily add material after it has been filed away. Some of you may be familiar with power tools, thus it may be tempting to use them to shorten your mouthpieces. If you own a lathe, please take the proper precautions and time to create a suitable and safe work holding scenario before attempting to cut the end of a mouthpiece. The lateral forces of removing metal at the end of a chucked mouthpiece are significant and there is a very real possibility that it could be ripped out of the chuck and across the room, possibly injuring you or someone nearby. Should you feel the need to use power tools, please only do so if you are truly qualified and understand how to do this safely. In place of a lathe, which I do no recommend for this purpose, a table top disc sander is a great alternative. I am not speaking of a hand held disc sander, only a table or floor mounted sander is safe for this purpose. You must again create a jig or work holding solution to achieve a square cut. Cut a perfectly square wood block approximately 4 x 2 x 1 inches and drill a hole just large enough to fit the shank of the mouthpiece through at the correct height to squarely trim the end. Use this jig in conjunction with a square guide way on the table of your disc sander and grind away. Remember, measure twice and grind once. Please use common sense and only perform work in a safe environment. If you do not understand how to use a power tool, please use a hand file instead. It is safer and you won't lose any fingers that way!

6 Comments

3/4/2013 10:08:28 pm

i have at bengie 65 and i like to try at mouth piece 5cw how mucch is the cost

Reply

3/14/2013 01:17:53 am

These are great informative articles Jason, so many players do not understand how really important the mouthpiece gap is and how it effects performance...

Reply

Nikola

7/28/2013 11:15:31 pm

Jason you are great!!! THANK YOU!!!!!!

Reply

9/11/2023 04:02:18 am

What are your thoughts on the trumpets that don't have a gap because the receiver is flush with the leadpipe? I have several old Conns, Holton's, York that are that way. Is this design better or poorer in your opinion?

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed