|

It's all about the sounds we create, right? We wouldn't pick up the trumpet day after day, year after year, if we didn't enjoy creating a series of beautiful, expressive, meaningful sounds. And our audience would prefer to listen to us communicate in an artful way. Making music is all about sound. If this is true, why do we so often overlook 50% of the sound-making equation? The mouthpiece and trumpet make up one half of the formula that holds the promise of amazing sound. The irony is that most people who think they are good at something give themselves too much credit. And this is often what holds them back from their full potential. In fact, the 50/50 debate is so heated that over 90% of the trumpet players I have polled believe that the player makes up of 90% of the sound equation. I've heard the words, "it's the player, not the horn" thousands of times. How then do you explain the thousands of high profile trumpet players who have worked intimately with trumpet makers to create something that fits their individual needs? Wouldn't these efforts be in vane if the player is 100% responsible for creating the sounds that immediately identify them, like a personal signature? Do they seek out custom trumpets and mouthpieces just to have their name engraved on their equipment? Having personally worked with hundreds of the most prolific and well known trumpet players alive today, I can safely say that pro players seek out new equipment because they recognize that they are only 50% of the sound equation. These are incredibly talented, hard working musicians dedicated to their craft, yet they would choose a custom trumpet and mouthpiece over something off the shelf. Leroy Jones is one of those people you never forget after hearing him just once. He performs with his band weekly at Preservation Hall in New Orleans. This man squeezes every last drop of traditional New Orleans Jazz out of his horn in a way that transforms space and time. He takes you back to the early 1920's with every note. And he sounds amazing even on the cheapest trumpets. Yet he sought out custom solutions to fit his very specific individual needs to further his musical expressions. And, like all trumpet players, he wanted increased endurance, comfort, efficiency, projection, and the list goes on. If you've never heard Leroy, I highly recommend you jump on a plane and go hear him live. If that isn't possible, at least check out his albums here. I rarely drop names as I believe every single person pursuing musical expression on a brass instrument deserves my unbiased attention, care, and time. With that said, I will drop a few names today, to offer some perspective and hopefully open your ears up to a few more great musicians that may inspire you. Charlton Singleton is one of the premiere trumpet players of our time. His expression on trumpet is only equaled by his captivating voice. Charlton is a founding member of Ranky Tanky, a band that will gracefully transport you into the Gullah culture of the Southeastern Sea Islands. You need to own his latest album Crossroads to truly understand what it means to communicate with your sound, both vocally and on a brass tube! Pete Rodriguez, another premiere Latin Jazz trumpet player of our time, is the son of the Pete "El Conde" Rodriguez who was literally one of the greatest Salsa Band leaders of all time. Like his father, Pete takes his Latin roots and music very seriously! His album Obstacles showcases Pete's talents rich in tonal expression, thought provoking complexity, and sheer virtuosity. Pete visits my shop yearly to discuss his musical goals, fine tune his mouthpiece setup, and further explore the latest innovations within the Muse Modular system. Jorge Vistel is perhaps the most prolific Jazz trumpet player in Europe today. I think of him as the Wynton of our time. Like Pete, Jorge is 100% devoted to his craft which leans heavily on complex phrasing, technical fireworks, and pure beautiful music. My dream is to someday host a concert featuring these two trumpet superstars in Denver. Jorge and his brother Maikel make up half of the Vistel Brothers Quartet currently based in Paris. Jorge will be taking delivery of the very first VPS Summit G4 made from laser sintered metal and solid hardwood late this year. Now that I've been sharing some of our clients, I wish I had time to continue with my very long list of trumpet players who will instantly inspire you to take your playing to the next level. However, I need to go build another Muse Modular trumpet for a client and change over the tooling on a lathe. I promise to share more soon.

Jason

0 Comments

There are typically three reasons trumpet players performance doesn't match their expectations. Technique/Fundamentals, Impedance mismatch, Equipment mismatch make up 99% of the issues I see on a daily basis. But there's one factor no one wants to discuss...

I don't know if you've noticed by my social media posts, but I typically work five long (12-hour) days every week broken up with two days of mountain time. With the change of seasons, we are also experiencing a change of production as I finish up the remaining Rumors & Dreams trumpets and a few custom Muse MMXX orders. Next on my bench will be a wide array of trumpet builds wrapping up the last 10 years of innovations in less than 50 days. I'm gathering up every single leadpipe, tuning slide, brace, finger ring, etc. on hand and assembling the remaining VPS Summit and Summit One, Muse, and X-series trumpets with the possibility of a few GS horns thrown in for good measure. My goal is to use every last component I have on hand in trumpet production before blazing into the future of trumpet design. I would like to pay homage to the last decade of hard work and dedication our team has invested to create career-changing solutions by focusing on these for much of this coming Summer. And for those of you wanting to own one of the last instruments I'll make in this era of trumpet design, now is the time to pull out your calendar and plan your trip to see me in Denver! The Rocky Mountains are calling and I'm happy to share ideas for day hikes, side trips, jaw dropping mountain drives, places to stay and eat, and much more. We get hundreds of visitors from out of state/country yearly, and every one of them has shared how much they loved their mini (or full) vacations to Colorado. To celebrate the past 10 years of Harrelson trumpet design, I will be offering special pricing in our showroom only. This means that visitors can save thousands on a brand new high efficiency trumpet this Spring and Summer. I estimate that we will sell out of the approximately 30 instruments I'm building by the end of September. You will also have special pricing on numerous single edition SpectraTone/5MM Mouthpiece bodies, inlaid finger buttons, and limited edition Mod Kits. These prices (and many items) will not be available to online customers. In 2021, I was given a new lease on life which has given me more freedom than I ever imagined was possible. Take it from someone who has been very fortunate to see every new sunrise, you need to prioritize what is important in life today. I challenge you to stop everything and take the next 10 minutes to truly reflect on what is important to you. When was the last time you intentionally picked up the phone to catch up with your best friend from high school? Who would be excited to meet you for lunch tomorrow? Where have you always wanted to visit, but never made the time or plans? There's someone out there who has inspired you over the years and would love to hear that from you. And likewise, you have very likely inspired others who would cherish a great conversation. Interrupt your life with something that makes you feel excited, alive, and vibrant. And if that includes a visit to my shop, I'll be here to share our time together. Whatever you do, get started right now!

Jason I often hear trumpet players ask one another, "how is the response on that horn?" when discussing equipment. I've asked thousands of musicians what this question means to them, and the responses are quite varied. In my experience working with clients, vocabulary used to describe the playability and sound of brass instruments is fairly limited and often vague. A term that one player defines as clean, articulate, and crisp, another will player will describe as sharp, abrupt, and crass. It seems we spend a lot of time saying things that we have not taken the time to fully define and understand. The word response is one of the most misunderstood terms used by brass players. One of the most common types of phrases I've heard is, "I can't play heavy horns because they are not responsive". Another, "that lightweight horn is unbelievably responsive." Technically speaking from a physics standpoint, both of these statements cannot be true when using the true definition of the word response or responsive. In fact, the opposite is true in both statements. So why do trumpet players so often say these kinds of things? The answer is primarily found in their first-hand experience behind the bell of the trumpet, rather than from the perspective of the listener on the other side of the bell. Many trumpet players have worked very hard to achieve results on a relatively difficult instrument, which tends to make them believe they are experts at their craft. But being great at playing an instrument does not necessarily mean you understand how it works or what is happening in terms of projection, tone quality, and overall results at the back of the club, hall, or auditorium. Listening on a higher level requires more than hearing what is happening behind the bell. Your audience is not sitting next to you, they are in front of you. And the instrument was specifically designed to project your creative sounds in their direction, not yours. To save your eyes reading on a computer screen, I've explored the words response and projection in this video while explaining how our B.R.A.S.S. components help achieve the results demanding trumpet playing requires. I have good news and something fun to keep you entertained this weekend. The good news is that pre-orders for our new Rumors & Dreams trumpets will be released next Wednesday morning. Even better news, you can get one for as low as $2800 if you're one of the first five customers to place your order. You can read more about how this will work here. I usually write a lot in my blog, but today I had too much to discuss on the origins of Rumors & Dreams. That's why I filmed a video to give you my personal history, research, and more on how our latest line of trumpets was named and designed. Don't miss the debut of this in-depth look at what could be your favorite trumpet, or pair of trumpets, of all time. And as always, feel free to leave your comments and questions below. I'm also available Monday and Tuesday to answer your questions before the pre-order launch, so you know exactly what you want to order before it happens. Jason I have made the decision to push back the release of Rumors & Dreams by at least two more weeks. This is in response to hopeful clients expressing concerns that they need more time to be financially ready to take advantage of release day pre-order discounts. And I plan to record the official release video using the new SpectraTone Red mouthpiece, which I am finishing next week. I personally believe the Rumors trumpet variation designed for lead and commercial playing, will sound best with the new SpectraTone Red mouthpiece.

Unrelated to R&D, September is the last month you can order a custom 3rd generation VPS Summit trumpet. If you love the smooth or crosshatch style crooks, this will be your last opportunity to place an order. We have a limited selection of these components remaining before they are retired forever. Laser welding techniques which produce the very smooth surface finishes will be replaced with two different processes, laser sintering and a screw array assembly system. Please email me with your intent to purchase a custom VPS Summit before the end of the month, so we can reserve the crook style of your choice. And finally, I want to mention the upcoming release of SpectraTone Red, which will be exclusive to a new crowdfunding platform known as Backerkit. Much like Kickstarter, the Backerkit platform will allow you to choose the exact size of your SpectraTone Red mouthpiece and place a pre-order with delivery expected within 60 days. To test this new system, we will launch our Dichroic Glass Mod Kits in the coming days. This will be a short campaign as we have limited inventory of this new Mod Kit designed to improve efficiency and overall playability. As always, feel free to contact me with your questions, or leave a comment here. Jason I have been innovating the 5MM Modular Mouthpiece System for well over a decade. The SpectraTone series is a direct descendant of the 5MM, and 100% compatible, so we use the terms interchangeably. Today, I'm introducing the next step in the evolution of modular mouthpieces. This innovation solves some challenges with cornet and flugel mouthpiece designs, and simplifies options. The new design integrates the Cup and Throat to be one piece, which simplifies assembly, and removes some options. You can still order the separate pieces we've offered in the past, if you already own the original version.

What does this mean to you? Well, now you can order a Modular Cornet or Flugel mouthpiece in the predetermined configurations I personally recommend. Since the Cup and Throat are integrated, the options are more straightforward and easy to order. You can see the new listing options here. Please know that I am making these new variations right now, so they will head to plating in approximately a week. This means your order today will likely be delivered within 30 days. - Jason I've polled both existing and prospective customers two years in a row with this question, "What price point would convince you to buy a Harrelson Trumpet?" Answers ranged from $7 to $12,500, and as you can imagine, the higher answers were submitted by current Harrelson owners. The average ideal price given by existing Harrelson clients was $5300 while the prospective owners' average was around $2760 when throwing out a few silly responses. It's interesting to note that trumpet players relying on Harrelson instruments on a daily basis offered a number nearly twice as high as those who have not yet experienced the advantages of higher efficiency, maximum bell resonance, and our exclusive variable performance system.

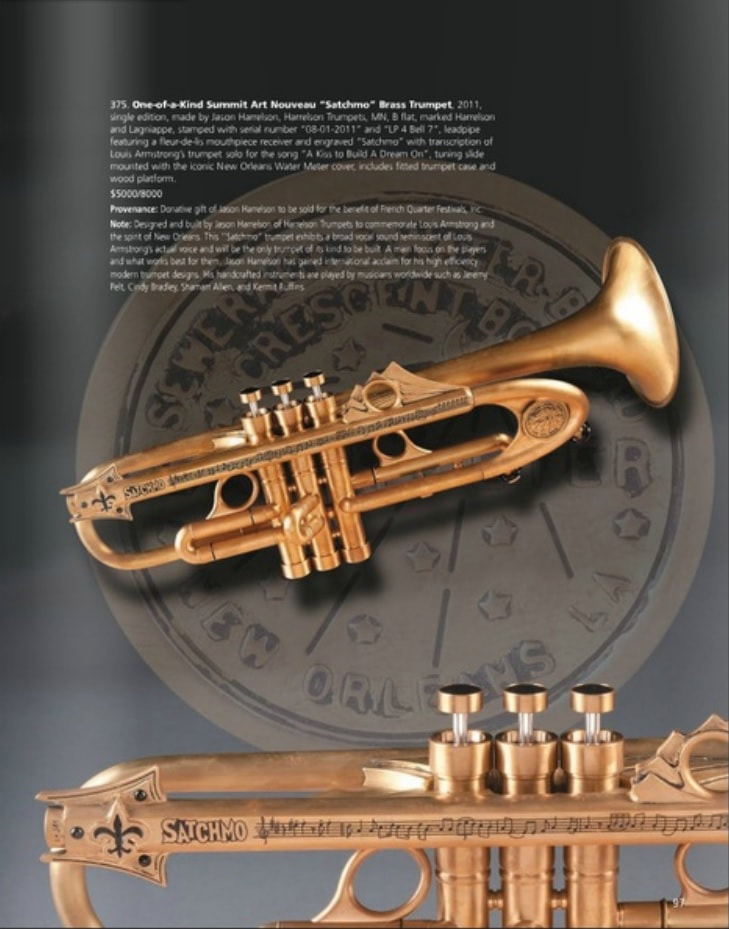

I did offer a $2500 trumpet for many years, which was known as the Bravura model. This instrument was my second model produced in any numbers, estimated around 300 instruments. The price started at $2500 back in 2005 or so, and crept up to $3995 several years later just before it was retired. Designed to balance efficiency and resonance, the Bravura model was a home run in terms of design, performance, and price. The Summit model replaced the Bravura, which has been our best selling model of all time with over 1,000 made to date. It was released in 2008 at $3995 and today it is priced in the $7000-8000 range thanks to a long list of improvements. These include the venturi gap receiver (VGR), which gives the player control over air flow, impedance, flexibility, and slotting with every setting possible in seconds. And the third generation fully machined leadpipe is available in 10 tapers that exhibit maximum efficiency. The SWE tuning slide optimizes impedance values, making the instrument very predictable in all registers. This means almost all of your effort remains in the standing wave until it resonates the bell while allowing every note to feel natural and comfortable. The VPS Summit, which includes our "variable performance system" upgrades is the current variation offered today. And it will be retired at the end of September. This will mark the end of an incredible era in trumpet design and manufacturing. The Summit was the first trumpet to feature a fully CNC machined tuning slide that is both laser welded and silver soldered to guarantee both maximum efficiency and optimum impedance ratios. The only other model to offer these advantages is the Muse. So what's my point? Well, many of you are asking for a $2500 trumpet, while the average reported price point that makes sense to own a Harrelson is $2760. So, I'm going to give you exactly what you're asking for, but there's a catch. I can only do it for a relatively small number of you. The new Rumors & Dreams limited edition series will be priced in the $4000-5000 range. But the first 5 customers who buy either model, can own one for as little as $2800. Consider this announcement as your one and only early warning to get your financial affairs in order asap. Like I said, only five people will get in on this opportunity. My team and I cannot afford to sell trumpets at a loss, so this is really one of those publicity stunts you see around the holidays. I'm doing this to get your attention, and because I know you'll tell your friends, colleagues, and students. I'm offering a $1200 opening day discount just to get everyone talking! But before you jump in with both feet, credit card in hand, ready to pull the trigger... You want to know about Rumors & Dreams, right? Rumors and Dreams are two similar, but different trumpets. Rumors is a commercial, lead, big band instrument, and Dreams is an all-around performer that works in every situation. Both have an attractive hex-milled feature on a number of B.R.A.S.S. components that are both functional and tie the theme together. That BRASS acronym you just read will be explained on the release date, but in a few words, BRASS components noticeably improve the playability of any brass instrument. The new Rumors & Dreams line is my answer to the modern day Bravura, which was so very successful in years past. The goal is to offer a horn that feels like home to each and every player. This is only possible with the VGR system, or by manually modifying the mouthpiece gap for each player. And that's exactly what I'm offering. When you choose the optional VGR upgrade, you'll have the world's most advanced fully adjustable impedance system ever designed, right at your finger tips. If you're on a strict budget, choose the included Zero Gap Receiver, and get ready to file down the end of your mouthpiece to optimize your setup. Either way, I will show you exactly how to make your new R&D trumpet fit like a glove in every register, on every note, at every dynamic level. I've studied brass acoustics since 1992, and I'm here to help you achieve success like you've never known. Along with this R&D launch, you'll have the opportunity to choose a bell that suits your projection and tonal color preferences. And you can get into our SpectraTone mouthpiece system at a discounted price. But the best part is our 0% financing payment plans for those of you who need a few months, or up to two years, to pay off your new custom trumpet. If you're not in the, "l'm ready to pay the balance on day one" club, then maybe you would rather make a $300 deposit with monthly payments in the $100-200 range. Yes, this will be an option! There are two things you need to remember. First, this new line of trumpets will likely be reserved very quickly upon release sometime in the coming days. And two, there will only be 31 Rumors and 36 Dreams trumpets available, ever. Watch for details in the coming days and feel free to leave a comment and share your thoughts. Jason Regardless if they would work well for you personally, what do you think of these finger rings? Aesthetically, are they interesting? If you're answer is a resounding no, then I respect your opinion. And if you love them, that's perfectly acceptable as well. Ironically, I made this set of finger rings in 2010 in Minneapolis on my first industrial CNC milling machine. In 2010, I asked the public the exact same question. Almost everyone hated not just the finger rings, but much of my work in general. The consensus at the time was that I was messing with something that was already perfect, and that artistic embellishments were completely unacceptable. At the time, I was introducing one unique design after another, stretching what was possible for me to create in terms of machining difficulty, design intent, artistic freedom, and personal preference. Around the same time, I built the very first Satchmo Summerfest trumpet, which was auctioned off with all proceeds benefiting the non-profit that hosts the event. The first Satchmo trumpet incorporated the opening line of A Kiss to Build a Dream On played by Louis Armstrong on the leadpipe. And it also garnered a similar level of hatred from the online community with people claiming it was too extravagant, heavy, artistic, etc. This did not discourage me in any way as, I've understood since I was very young that, people are very slow to catch on. For instance, when I was around 10 years old I designed and built a Christmas ornament for my mother that used one AA battery to power a motor and an array of LED lights. Everything was handmade and soldered in my bedroom. My Mom thought this was amazing, or at least told me so, and she believed people would buy ornaments like this at the store. A few years later, I had evolved my skills to animating and lighting up decorations for Halloween. It was another 25 years before I saw anything similar for sale in the store, and these types of decorations are now overly popular, in my opinion. The truth is that I wasn't crazy about decorating for holidays. I simply enjoyed the exercise and challenge of making the animated designs. The funny thing about these Flames finger rings is that not only do people judge with their preconceived notions and eyes, but they also miss out on what is beneath. They miss the advantages resulting from 30+ years of researching SWE (standing wave efficiency) Technology, Maximum Bell Resonance, the Variable Performance System, and so much more. I haven't been focused on making cool looking horns all these years. I've been innovating the instrument we love to be easier and more rewarding to play every day. The artistic side has really just been a way to tie the aesthetics together with the technology to create playable art.

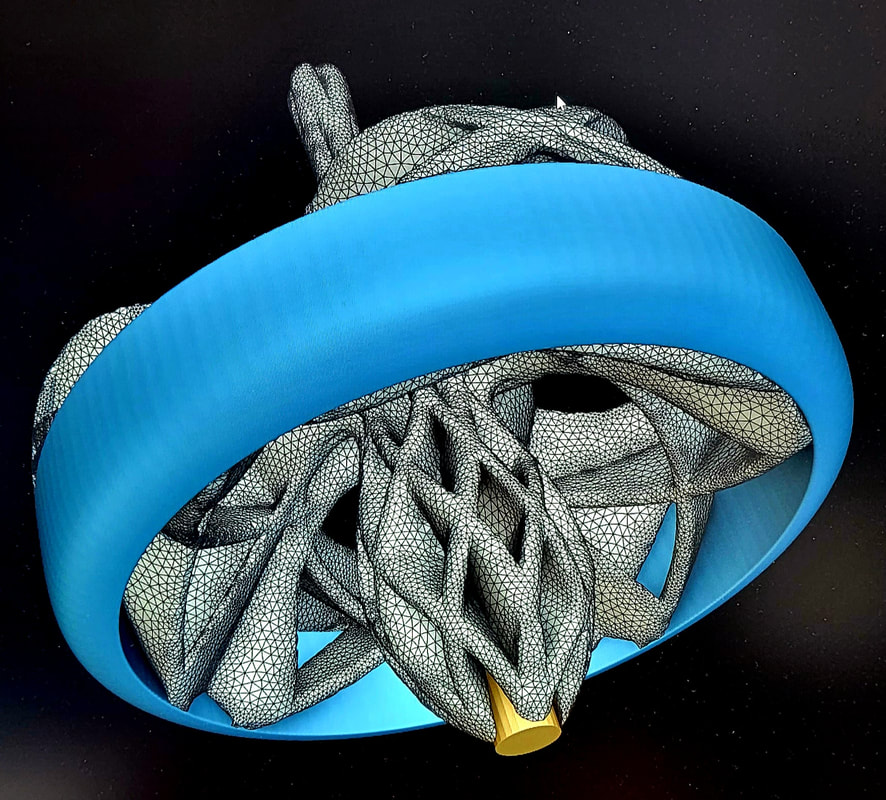

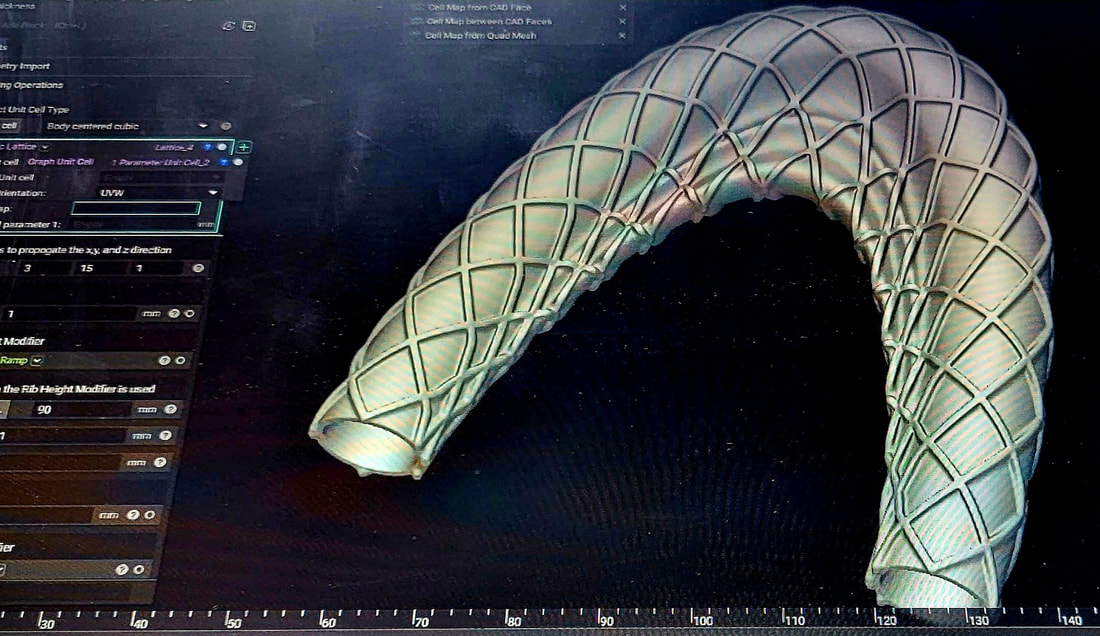

Full disclosure, I never have liked the look of the Flames finger rings. I simply made them to see if it was possible. When machinists visit my shop, they sometimes pick out one of these rings and tell me it must have been very difficult to make. Well, in 2010 my skills were not what they are today, and yes, they were very difficult to machine. That's exactly why I designed and made them. Jason I just finished giving another shop tour. This was probably my 7th tour this month as we've had a lot of visitors this Summer. And on the tours, we discuss the future of Harrelson Trumpets along with our thirty-one year history. Tracing three decades of Harrelson research and innovation is a lot of fun. And we have numerous artifacts to show along the way, from the very first trumpet I ever built to instrument designs in progress that will be released in 2024. Shop tours are a constant reminder for Jen, Christine, and I to process where we've been, where we are today, and where we're headed. There's a robot arm waiting to be installed on the VMC along with a pneumatic vise to automate the production of bracing, tuning slides, and bell crooks. And there's a table covered with laser sintered metal parts showcasing the possibilities of modern 3D printing technology. Some of these parts fit our trumpets and are made in a wide array of materials including; aluminum, titanium, inconel, stainless steel, and nylon. All of these example parts are lighter, stronger, and better than their counterparts machined in brass. You will soon see entirely new generations of trumpets and mouthpieces made by combining laser sintering and CNC machining technologies. Where does that put us today? While I'm not 100% certain of the future, I do plan to push forward utilizing the latest Aerospace lightweighting software, laser sintering, and CNC machining to essentially enter a new era of trumpet design. This means that our current offerings of laser welded and silver soldered tuning slides and bell crooks will no longer be in production. In fact, the last production run using these techniques was in January. And with these innovations, our third generation of VPS Summit trumpets will also come to an end on September 30th. This is important for two reasons. One, the next generation of VPS Summit trumpets (G4) will debut this Autumn, at a higher price point. And two, our best selling trumpet design to date, the 3rd generation Summit will be retired ending the production run after 8 years. This means the Summit trumpets you see on our website are literally a few of only a handful of examples available this Summer. And this brings me to some really interesting and fun announcements. First, the Summit Illusion series was just released, which is a limited series of four variations. Two of these were designed for Jazz combo, one for Lead, and the last for versatility. We sold the first of this set a few days ago, and based on feedback from visitors, we expect the remaining three to sell this month. You can see the Summit Illusion here along with several YouTube video reviews. And through this Friday, you will receive a SpectraTone Blue mouthpiece, ProTec case, and worldwide shipping at no charge when you purchase an Illusion series trumpet. The next big announcement, I will be finishing several unique and rare builds in the Summit line featuring variations in bracing, engraving, inlays, and finishes. You may want to read every message I send through the end of the Summer just to see photos of these instruments. There's one exception to everything mentioned above. Those of you on my build list for a Summit G3 series trumpet may take delivery of your instrument based on your original order agreement. And if you're considering a new Summit in the current edition, you still have six weeks to place your order and set up a payment plan for up to 24 months. Every current or new Summit order is placed in our order cabinet WITH the required parts pulled from inventory. We are out of some style tuning slides and bell crooks permanently, and I see we only have 3 sets of style R remaining. Once these are sold or reserved, they are gone forever. I'm honored to have been chosen to build custom trumpets for well over two thousand individual trumpet performers, and look forward to exploring the future of brass playing with our Harrelson family. Jen, Christine, and I often discuss how our company is really the culmination of the shared vision and support of our entire clientele. Thank you all for this unbelievably rewarding opportunity. Jason |

Jason Harrelson

Inventor, Musician, Educator and Founder of Harrelson Trumpets, Trumpet Momentum and Harrelson Momentum. Archives

July 2024

|

RSS Feed

RSS Feed